R50/53 Pulley revamp - supercharger, idler, crankshaft

#1

Pulley revamp - supercharger, idler, crankshaft

I'm planning on ordering an ATI damper to replace the lightweight Alta crank pulley that's currently on my car when I bought it, along with a supercharger pulley kit from WMW. I might just end up taking it to my mechanic to have it done, considering the fact that I don't have any of the pulley puller tools nor an impact wrench (for the crank pulley & supercharger) which seems necessary considering it's an automatic transmission.

Should I attempt to do this myself, or just take it into the shop where the cost for them to do it is almost the same as buying all the necessary tools? Also, anything else I should look into if this kind of work is being done? (Timing chain cover gasket, timing chain itself, timing guides?)

Should I attempt to do this myself, or just take it into the shop where the cost for them to do it is almost the same as buying all the necessary tools? Also, anything else I should look into if this kind of work is being done? (Timing chain cover gasket, timing chain itself, timing guides?)

#3

I'm planning on ordering an ATI damper to replace the lightweight Alta crank pulley that's currently on my car when I bought it, along with a supercharger pulley kit from WMW. I might just end up taking it to my mechanic to have it done, considering the fact that I don't have any of the pulley puller tools nor an impact wrench (for the crank pulley & supercharger) which seems necessary considering it's an automatic transmission.

Should I attempt to do this myself, or just take it into the shop where the cost for them to do it is almost the same as buying all the necessary tools? Also, anything else I should look into if this kind of work is being done? (Timing chain cover gasket, timing chain itself, timing guides?)

Should I attempt to do this myself, or just take it into the shop where the cost for them to do it is almost the same as buying all the necessary tools? Also, anything else I should look into if this kind of work is being done? (Timing chain cover gasket, timing chain itself, timing guides?)

whatever problems you encounter, think about a solution to resolve it. If your stuck, reach out to NAM.

#4

do it yourself, you will learn more and it will expand your knowledge and confidence to get future jobs done. I am in the middle of it now and it is not that bad... I can say you will need to lift/lower the motor multiple times during the work. Also, the timing cover o-rings, one liked to fall out on me so I put a dab of sealant on it in 2 spots to hold it in place. The biggest issue I had was getting the crank pulley bolt off. Have an impact gun, electric said to be 350# tq and initially it was doing nothing for it. Battery had a good charge, not full but half to 2/3 full, extension on it to the socket. Still would not break free... ended up charging up battery 100% and removing the extension and it came right off on the next attempt. I think the next challenge is going to be getting the torque on the crank bolt. nd-photo.nl mentioned he used a breaker bar on the axle nut to secure his crank bolt. Wont work on mine as mine is an open diff transaxle (I think, mine just spun). I may be able to apply that technique using the DS axle.

whatever problems you encounter, think about a solution to resolve it. If your stuck, reach out to NAM.

whatever problems you encounter, think about a solution to resolve it. If your stuck, reach out to NAM.

In terms of an impact wrench, I was planning on getting this . It says it can do 210 ft/lb of torque, hopefully that would be enough to push the crankshaft pulley off?

As for the pulley puller tools I thought that WMW did rentals, but that might have changed. I'd rather get the right tool specific for the Mini than just a generic harmonic balancer puller.

Last edited by dayman; 10-27-2020 at 07:37 AM.

#5

Alright, I'll have to think about it. I don't mind doing it myself, I'm just worried I'll get stuck and then I can't drive the car to the shop in the event something goes wrong. I live in NYC so an empty parking lot has been my garage of choice for working on the Mini. Recently I attempted to replace my power steering hoses, ended up getting too dark and I had to drive the car without power steering to the shop the next morning because I couldn't get at the high pressure hose - so I'm just wary about effing it up.

In terms of an impact wrench, I was planning on getting this Makita. It says it can do 210 ft/lb of torque, hopefully that would be enough to push the crankshaft pulley off?

As for the pulley puller tools I thought that WMW did rentals, but that might have changed. I'd rather get the right tool specific for the Mini than just a generic harmonic balancer puller.

In terms of an impact wrench, I was planning on getting this Makita. It says it can do 210 ft/lb of torque, hopefully that would be enough to push the crankshaft pulley off?

As for the pulley puller tools I thought that WMW did rentals, but that might have changed. I'd rather get the right tool specific for the Mini than just a generic harmonic balancer puller.

OK, I might back peddle some now that I hear your in a parking lot... that would suck to be stuck. I've done work on my old Audi TT in a rock driveway in the summer, it absolutely sucked... I even went and created a tent to keep the work area cool. It might take a day or two the first time you do it... Plus it needs to be reasonably clean.

I have been taking my time, stopped work if there was any question & did the research before proceeding. If the empty parking lot is a garage with shelter, different story. Years back I worked on my truck in the underground parking garages at the BEE (big evil empire aka microsoft), middle of winter, 3 levels down and while it was OK, it was still pretty cold.

The following users liked this post:

ssoliman (10-27-2020)

#6

OK, I might back peddle some now that I hear your in a parking lot... that would suck to be stuck. I've done work on my old Audi TT in a rock driveway in the summer, it absolutely sucked... I even went and created a tent to keep the work area cool. It might take a day or two the first time you do it... Plus it needs to be reasonably clean.

I have been taking my time, stopped work if there was any question & did the research before proceeding. If the empty parking lot is a garage with shelter, different story. Years back I worked on my truck in the underground parking garages at the BEE (big evil empire aka microsoft), middle of winter, 3 levels down and while it was OK, it was still pretty cold.

I have been taking my time, stopped work if there was any question & did the research before proceeding. If the empty parking lot is a garage with shelter, different story. Years back I worked on my truck in the underground parking garages at the BEE (big evil empire aka microsoft), middle of winter, 3 levels down and while it was OK, it was still pretty cold.

#8

I'm not really sure if they have anything of that nature, real estate is tight in Brooklyn. An indoor parking garage would be good, but you have to pay and I'm sure they wouldn't want someone tearing a car apart in there.

The following users liked this post:

ssoliman (10-27-2020)

#9

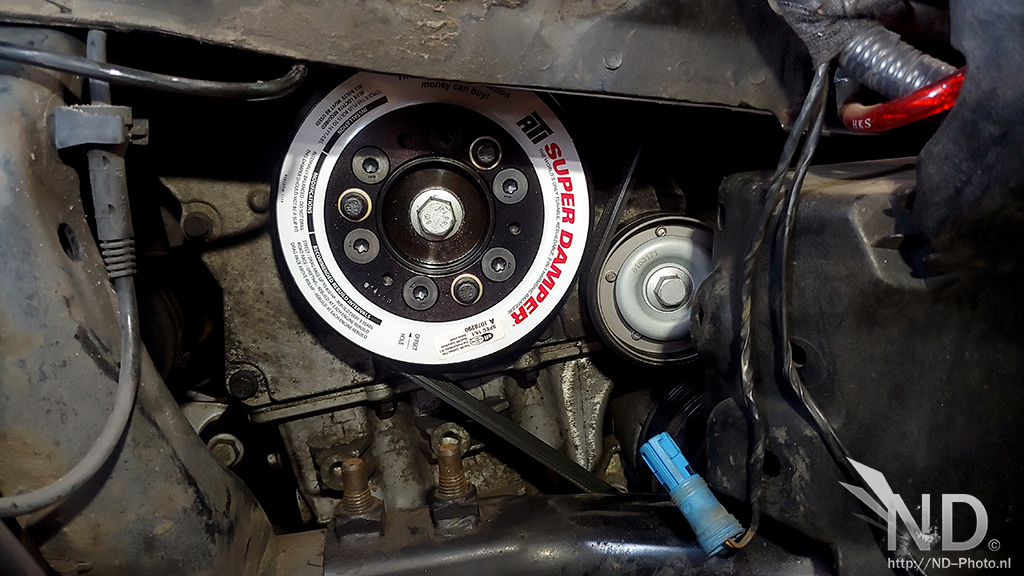

Its perfectly doable in your home garage or on the driveway. You only need a single axle stand for this. I recently changed it myself.

This is my top tip for torqueing the crank bolt.

More pics here: https://www.northamericanmotoring.co...rogress-8.html

This is my top tip for torqueing the crank bolt.

More pics here: https://www.northamericanmotoring.co...rogress-8.html

The following 2 users liked this post by nd-photo.nl:

ssoliman (10-27-2020),

steve05ram360 (10-27-2020)

#11

The following 2 users liked this post by dayman:

ssoliman (10-28-2020),

WayMotorWorks (10-29-2020)

#12

#14

The following 2 users liked this post by Errk:

ssoliman (10-28-2020),

WayMotorWorks (10-28-2020)

#16

#17

Do not use a impact wrench for removing it, see the movie below what happens when you do.

www.youtube.com/watch?v=Yfeikv2SsjQ

www.youtube.com/watch?v=Yfeikv2SsjQ

The following users liked this post:

ssoliman (10-30-2020)

#19

I purchased some anti seize compound that I was going to apply to the bolt threads when the time comes. Would it be better to start the bolt using a breaker bar and finish the rest with the impact, but with a low setting maybe? I just got the tool today, and the markings on the bolt head say JL 8.8

#20

I purchased some anti seize compound that I was going to apply to the bolt threads when the time comes. Would it be better to start the bolt using a breaker bar and finish the rest with the impact, but with a low setting maybe? I just got the tool today, and the markings on the bolt head say JL 8.8

when you go to torque the new crank pulley, put a screwdriver in each rotor. That is how I got mine torqued down, everything else just allowed the motor to rotate.

#21

On mine, once the crank pulley started to move, a ratchet was all that was needed. I would stick with that. Not sure on the SC pulley though since I had the Alta installed and only need to swap the cover.

when you go to torque the new crank pulley, put a screwdriver in each rotor. That is how I got mine torqued down, everything else just allowed the motor to rotate.

when you go to torque the new crank pulley, put a screwdriver in each rotor. That is how I got mine torqued down, everything else just allowed the motor to rotate.

Did it in the parking lot of Ikea, and only got in a little bit of trouble by security at the very end.

The following 2 users liked this post by dayman:

ssoliman (11-08-2020),

steve05ram360 (11-08-2020)

#22

I finally got the new S/C pulley on and idler pulley, the supercharger really screams now combined with the intake. Took absolutely forever though, and got the pulley tool stuck on the crash tube for like 15 minutes but it's on and it works. Car is still leaking quite a lot of oil, so that's nice.

Did it in the parking lot of Ikea, and only got in a little bit of trouble by security at the very end.

Did it in the parking lot of Ikea, and only got in a little bit of trouble by security at the very end.

#23

Thread

Thread Starter

Forum

Replies

Last Post

sea_to_sky

Drivetrain (Cooper S)

39

11-08-2005 02:32 PM