R56 New brake pads and a turbo thermal/heat shield>>>

#1

New brake pads and a turbo thermal/heat shield>>>

Got to a couple mods yesterday...

First the M7 turbo thermal shield (purchased from 1FastMINI)...nicely made and piece of cake to install... only tools you need is a 10 mm socket w/ 5" extension (to remove 2 OEM heat shield bolts) and 5 mm allen wrench to install M7 heat shield bolts.

Exterior...satin black finish matches engine bay color/finish perfectly

Inside showing the "Aerogel is nanotechnology with amazing heat rejection qualities (which is why NASA is also using this material in a variety of applications)"

And installed>>>

Results (using a Raytek MT6 laser thermal reader):

Pre heat shield install (OEM set up)

Turbo exhaust side: 370-450 deg F

Turbo air side: 160 deg F

Under bonnet at scoop: 124 deg F

Post M7 heat shield install

Heat shield housing exterior: 130 deg F

Under bonnet at scoop: 112 deg F

Looks like it is a winner...10% reduction in under bonnet scoop temps

Now to brake pad install... if you have worked on any sliding caliper style brake set up then you know what to expect with the MINI brakes... not difficult at all. Tools needed:

13 mm socket

17 mm open end

13 mm open end or ratchet box

brake cleaner (just if you want to clean calipers up a bit)

Loctite blue

First fronts.. I went with EBC Red (Ceramic) pads since my pads of choice Porterfield does not make R4S pads for the MINI S... there is a outer and inner pad due to brake sensor clip on the inner pad (driver front only)>>

To remove caliper unbolt 13 mm bolt top and bottom (will also require securing retaining nut with 17 mm open end

Of course do not hang caliper by brake line...simple set on top of rotor... EBC pads installed

and caliper re-installed (make sure to use Loctite blue on 13mm bolts...on all caliper bolts)

I have the JCW slotted front rotors that I am sending to have zinc plated and then will switch out OEM rotors to the JCW

Rear pads..

Since I have switched out the pads with less than 200 miles on the car, I did not have any need nor issue with compressing the rear brake caliper piston.

NOTE: if you change out pads with 5000 mile +++ on the pads you will need a piston compression tool that not only compresses but also rotates piston which allows for the piston to be compressed.

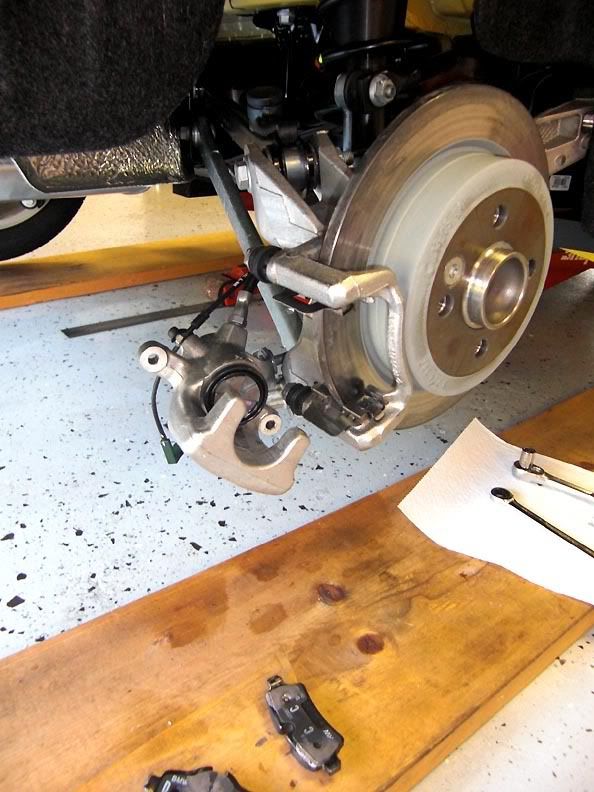

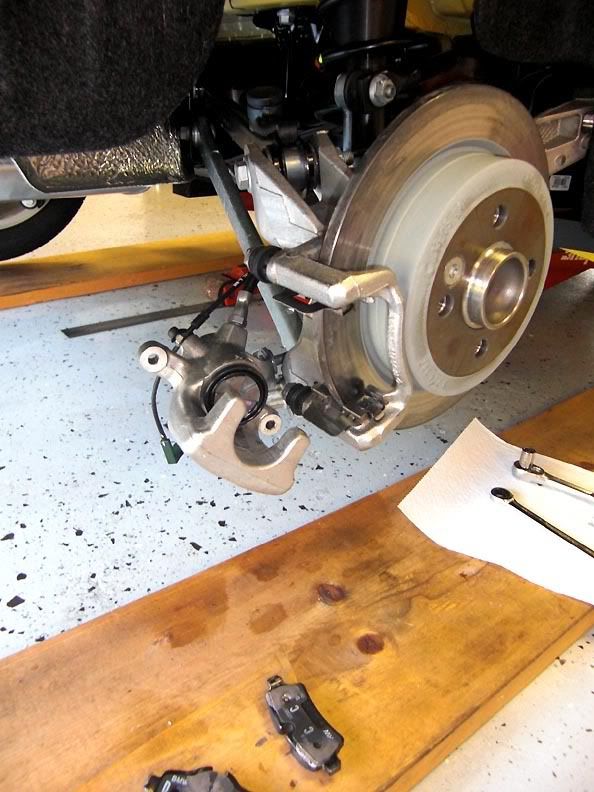

You need to use a 13 mm socket (right rear... on left rear due to lower bolt clearance issue will need a 13 mm open end or box ratchet) and a 13 mm open end wrench)

The wire/green device hanging down is the rear brake sensor removed

Now the caliper removed>>

Caliper simply hangs from the emergency brake cable...stiff enough to hold caliper as seen in the pic. Also I treated the brake rotor outer edge with OxySolv to remove rust and leave a zinc phosphate coating...just a 'dress up' thing...hate rusty rotors.

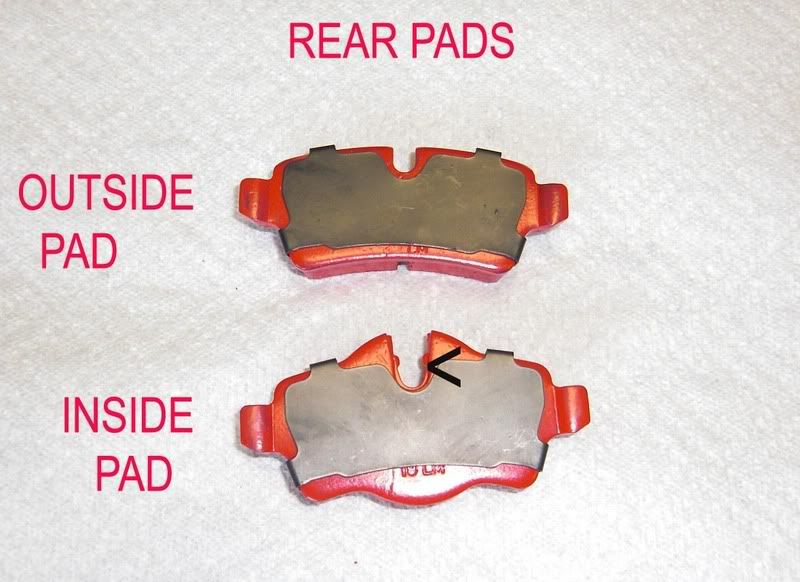

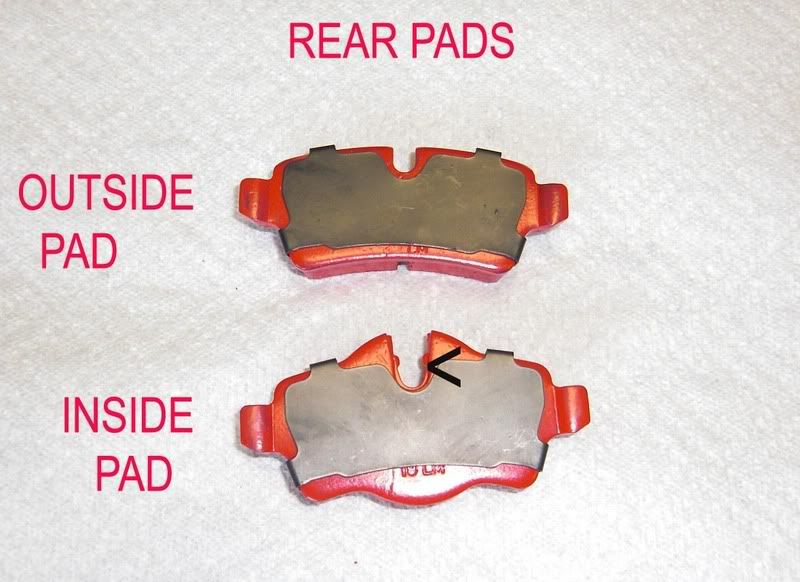

For the rear brakes they too have and inside pad (not sensor clip site) and a outer pad>>

Caliper re-installed... make sure to use Loctite blue on caliper bolts and also note brake sensor (green device)...rear sensor is only on the right rear caliper

That is really it... not hard and just take your time. Oh yes...why switch pads?? Better bite and lower amounts of brake dust

Michael

First the M7 turbo thermal shield (purchased from 1FastMINI)...nicely made and piece of cake to install... only tools you need is a 10 mm socket w/ 5" extension (to remove 2 OEM heat shield bolts) and 5 mm allen wrench to install M7 heat shield bolts.

Exterior...satin black finish matches engine bay color/finish perfectly

Inside showing the "Aerogel is nanotechnology with amazing heat rejection qualities (which is why NASA is also using this material in a variety of applications)"

And installed>>>

Results (using a Raytek MT6 laser thermal reader):

Pre heat shield install (OEM set up)

Turbo exhaust side: 370-450 deg F

Turbo air side: 160 deg F

Under bonnet at scoop: 124 deg F

Post M7 heat shield install

Heat shield housing exterior: 130 deg F

Under bonnet at scoop: 112 deg F

Looks like it is a winner...10% reduction in under bonnet scoop temps

Now to brake pad install... if you have worked on any sliding caliper style brake set up then you know what to expect with the MINI brakes... not difficult at all. Tools needed:

13 mm socket

17 mm open end

13 mm open end or ratchet box

brake cleaner (just if you want to clean calipers up a bit)

Loctite blue

First fronts.. I went with EBC Red (Ceramic) pads since my pads of choice Porterfield does not make R4S pads for the MINI S... there is a outer and inner pad due to brake sensor clip on the inner pad (driver front only)>>

To remove caliper unbolt 13 mm bolt top and bottom (will also require securing retaining nut with 17 mm open end

Of course do not hang caliper by brake line...simple set on top of rotor... EBC pads installed

and caliper re-installed (make sure to use Loctite blue on 13mm bolts...on all caliper bolts)

I have the JCW slotted front rotors that I am sending to have zinc plated and then will switch out OEM rotors to the JCW

Rear pads..

Since I have switched out the pads with less than 200 miles on the car, I did not have any need nor issue with compressing the rear brake caliper piston.

NOTE: if you change out pads with 5000 mile +++ on the pads you will need a piston compression tool that not only compresses but also rotates piston which allows for the piston to be compressed.

You need to use a 13 mm socket (right rear... on left rear due to lower bolt clearance issue will need a 13 mm open end or box ratchet) and a 13 mm open end wrench)

The wire/green device hanging down is the rear brake sensor removed

Now the caliper removed>>

Caliper simply hangs from the emergency brake cable...stiff enough to hold caliper as seen in the pic. Also I treated the brake rotor outer edge with OxySolv to remove rust and leave a zinc phosphate coating...just a 'dress up' thing...hate rusty rotors.

For the rear brakes they too have and inside pad (not sensor clip site) and a outer pad>>

Caliper re-installed... make sure to use Loctite blue on caliper bolts and also note brake sensor (green device)...rear sensor is only on the right rear caliper

That is really it... not hard and just take your time. Oh yes...why switch pads?? Better bite and lower amounts of brake dust

Michael

Last edited by MeloR56; 07-23-2008 at 06:16 AM.

#6

What JCR1960 notes PLUS a safety factor... considering the OEM turbo shield can get very hot (over 220 deg F) and the O2 sensor at the turbo can get to 500+ deg F you really do not want to touch those areas by accident  ... after driving about, the M7 turbo shield (which covers over...not encapsulate so air is still moving over turbo...the hot OEM shield and O2 sensor) surface was reading 130 deg F...so a accidental touch is nothing. M7 device is a nice addition...

... after driving about, the M7 turbo shield (which covers over...not encapsulate so air is still moving over turbo...the hot OEM shield and O2 sensor) surface was reading 130 deg F...so a accidental touch is nothing. M7 device is a nice addition...

Michael

... after driving about, the M7 turbo shield (which covers over...not encapsulate so air is still moving over turbo...the hot OEM shield and O2 sensor) surface was reading 130 deg F...so a accidental touch is nothing. M7 device is a nice addition...

... after driving about, the M7 turbo shield (which covers over...not encapsulate so air is still moving over turbo...the hot OEM shield and O2 sensor) surface was reading 130 deg F...so a accidental touch is nothing. M7 device is a nice addition...Michael

#7

So the heat's not going to melt your bonnet scoop - but it has to go somewhere. Is there any risk at all to the heat shield? It's not going to, say, inadvertently redirect some super hot air and melt a hose, spraying radiator fluid all over the place, disabling the vehicle just as I was on my way to pick up Natalie Portman for the date she finally gave in to, is it?

Trending Topics

#9

4th Gear

iTrader: (1)

Joined: Jul 2007

Posts: 434

Likes: 0

From: Round on the ends, Hi in the middle.

So the heat's not going to melt your bonnet scoop - but it has to go somewhere. Is there any risk at all to the heat shield? It's not going to, say, inadvertently redirect some super hot air and melt a hose, spraying radiator fluid all over the place, disabling the vehicle just as I was on my way to pick up Natalie Portman for the date she finally gave in to, is it?

#10

Thanks!

#11

Michael

#12

Stay tuned!

#16

#17

turbos love heat, as long as it is not oil starved there is no issue... thermal coatings do an even better job than these shields..

#20

Torque values?

This write-up was so helpful as I replaced my stock pads. Thank you. I do have two questions: 1) what are torque values for 13mm caliper bolts (or does it really matter)? 2) You did not use any kind of lube on piston surfaces and other metal-to-metal surfaces - do I need to? Especially given that my car is an '08 with only 2,400 miles. Thanks again!

#21

1) what are torque values for 13mm caliper bolts (or does it really matter)? Most auto techs go by 'til it feels tight  The caliper to bracket slide bolt is 28-32 ftlbs; the caliper bracket to hub bolt is 90-95 ftlbs... neither does not have to be 100% on the mark.

The caliper to bracket slide bolt is 28-32 ftlbs; the caliper bracket to hub bolt is 90-95 ftlbs... neither does not have to be 100% on the mark.

2) You did not use any kind of lube on piston surfaces and other metal-to-metal surfaces - do I need to? The "lube" is really an anti squeal (reduces high frequency vibrations at pad to piston or caliper contact during braking)... most use some sort of anti squeal material..in the case of the EBC pads the black backing pad (as seen in the pics) is now being included with the EBC pads and serves that purpose

The caliper to bracket slide bolt is 28-32 ftlbs; the caliper bracket to hub bolt is 90-95 ftlbs... neither does not have to be 100% on the mark.

The caliper to bracket slide bolt is 28-32 ftlbs; the caliper bracket to hub bolt is 90-95 ftlbs... neither does not have to be 100% on the mark.2) You did not use any kind of lube on piston surfaces and other metal-to-metal surfaces - do I need to? The "lube" is really an anti squeal (reduces high frequency vibrations at pad to piston or caliper contact during braking)... most use some sort of anti squeal material..in the case of the EBC pads the black backing pad (as seen in the pics) is now being included with the EBC pads and serves that purpose

#24

Results (using a Raytek MT6 laser thermal reader):

Pre heat shield install (OEM set up)

Turbo exhaust side: 370-450 deg F

Turbo air side: 160 deg F

Under bonnet at scoop: 124 deg F

Post M7 heat shield install

Heat shield housing exterior: 130 deg F

Under bonnet at scoop: 112 deg F

Looks like it is a winner...10% reduction in under bonnet scoop temps

************************************************

Thats all that I have quantified and trying not to base on subjective views

Michael

#25

I think the issue is POINT OF SOURCE of turbo heat and HOW the heat is distributed. The M7 turbo shield distributes heat more evenly rather the OEM set up which can allow turbo heat to concentrate at the hood scoop area, thus my earlier (about 2 months ago) where I measured heat etc>>>

Results (using a Raytek MT6 laser thermal reader):

Pre heat shield install (OEM set up)

Turbo exhaust side: 370-450 deg F

Turbo air side: 160 deg F

Under bonnet at scoop: 124 deg F

Post M7 heat shield install

Heat shield housing exterior: 130 deg F

Under bonnet at scoop: 112 deg F

Looks like it is a winner...10% reduction in under bonnet scoop temps

************************************************

Thats all that I have quantified and trying not to base on subjective views

Michael

Results (using a Raytek MT6 laser thermal reader):

Pre heat shield install (OEM set up)

Turbo exhaust side: 370-450 deg F

Turbo air side: 160 deg F

Under bonnet at scoop: 124 deg F

Post M7 heat shield install

Heat shield housing exterior: 130 deg F

Under bonnet at scoop: 112 deg F

Looks like it is a winner...10% reduction in under bonnet scoop temps

************************************************

Thats all that I have quantified and trying not to base on subjective views

Michael

Lower the intake temp is good, but how much more temp can the turbo take? Yes we have more peak power with colder intake temp, but with a hotter turbo it will most likely reduce the time you can stay on overboost??

Last edited by nickminir56; 12-14-2008 at 05:46 PM.