R56 R56/N14 No start after Timinng chain install

#1

R56/N14 No start after Timinng chain install

Hello,

I have a 2010 Mini Cooper S. Car has right at 40K on the clock and until last month was my wife’s pride and joy. Still is in fact, just right now torn apart in my garage so… yea. I just got done changing out the timing chain. A project I am hoping I never have to do again. At any rate, I used all the special tools and what not to complete the task. I put everything together and now the car won’t start.

I will try and explain my problem in as much detail as possible so that you all can understand what is going on.

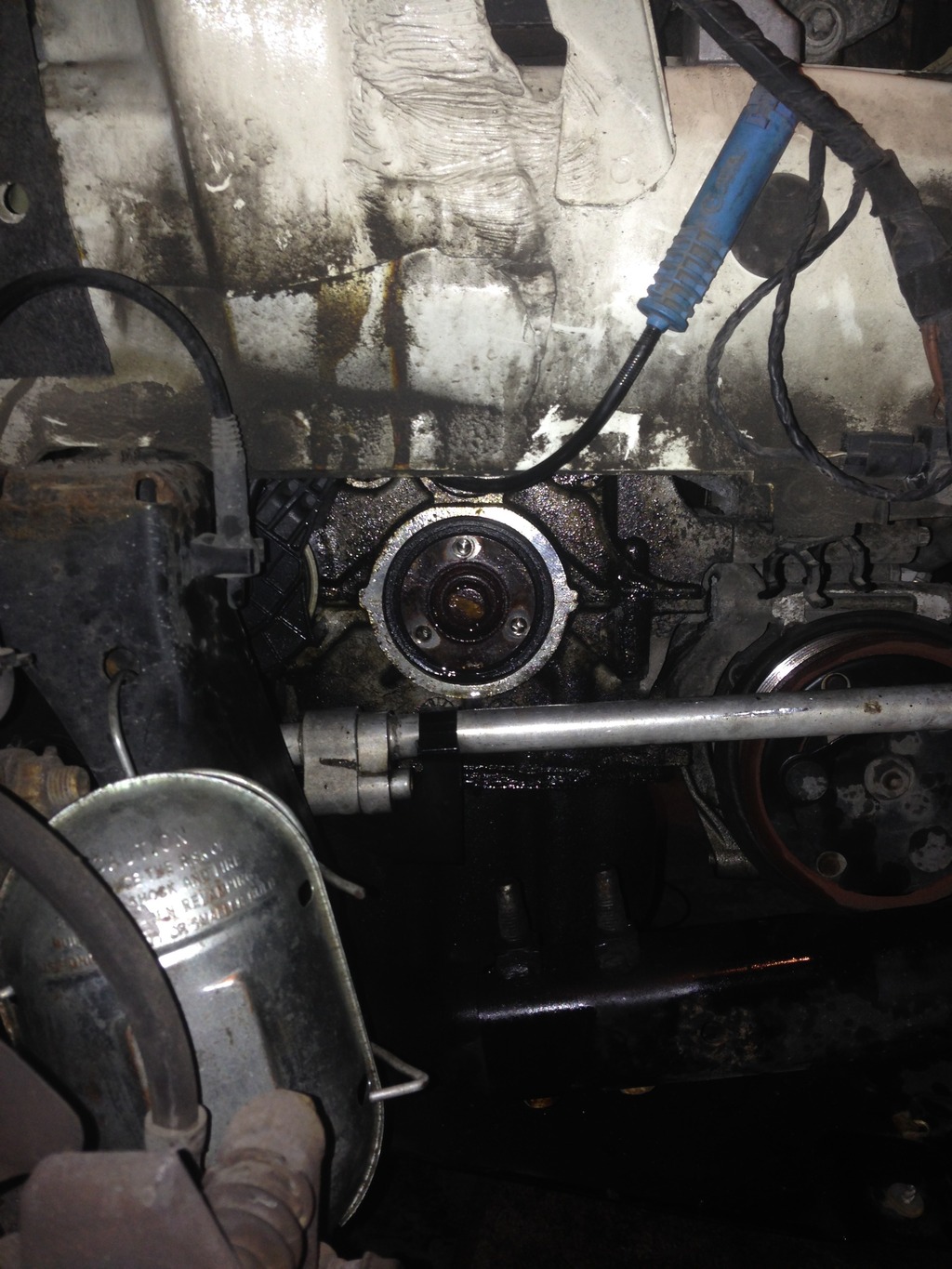

First like I said I used the cam locking tools per the tech order. And proceeded to cuss my way through taking the timing chain out. I did remove the water pump tensioner as I found it necessary to get the bottom chain guide bolt out. I reinstalled everything in the same order I took it out I worked from the bottom to the top. Everything went together pretty well. After I was sure I was done moving things around I took the cam locking tools off. They were easy to take off, i.e. no binding or anything. I turned the motor over by hand a few times just to make sure the engine was free and clear. I did notice that it is real easy to turn then gets tough for a brief sec then easy again. I did some reading and figured this was due to the VANOS gear the way snaps over. I slapped the valve cover on and put the plugs in. I verified I had all my tools and tried to start it. At first nothing because the battery is dead.. this is frustrating because it has been unhooked for the length of the project. I hook another battery up and try and start. The engine just spins and spins… Nothing does not even try and start. I thought I heard a slight backfire…. Nevertheless, nothing. I hit the ignition to stop the starter from overheating. I quickly took the valve cover off and could not see anything out of the norm. The chain was tight and everything seemed to be where it needed to be. So I took to turning the motor over by hand again just like the first time really easy then tough for a brief min and so on and so on. I took a look online and could find nothing that fit the bill so thus this long post. I did rotate the motor back around and put the cam locking tools back on just to ensure that had not skipped timing…. My gut tells me this is the only thing I could have messed up. The tools go on without an issue, I verified that the numbers are face up on the cams and that all three parts of the tool line up and bolt down. When the car turns over it spins just fine. There is no catch or horrible sounds like valves hitting.. it just spins.

when I figure out how to add pics/vids I will put those up here as well

Other thins I have checked….

Every fuse on the car

I Googled this problem so hard I ended up on page 5 of google results.

I have the Chilton’s manual and went through that.

I really hope someone out there has dealt with this before and can tell me a way to ensure that I have the timing correct and if I do what the heck is wrong. Car ran great up until I took it apart

Thanks for reading!!

I have a 2010 Mini Cooper S. Car has right at 40K on the clock and until last month was my wife’s pride and joy. Still is in fact, just right now torn apart in my garage so… yea. I just got done changing out the timing chain. A project I am hoping I never have to do again. At any rate, I used all the special tools and what not to complete the task. I put everything together and now the car won’t start.

I will try and explain my problem in as much detail as possible so that you all can understand what is going on.

First like I said I used the cam locking tools per the tech order. And proceeded to cuss my way through taking the timing chain out. I did remove the water pump tensioner as I found it necessary to get the bottom chain guide bolt out. I reinstalled everything in the same order I took it out I worked from the bottom to the top. Everything went together pretty well. After I was sure I was done moving things around I took the cam locking tools off. They were easy to take off, i.e. no binding or anything. I turned the motor over by hand a few times just to make sure the engine was free and clear. I did notice that it is real easy to turn then gets tough for a brief sec then easy again. I did some reading and figured this was due to the VANOS gear the way snaps over. I slapped the valve cover on and put the plugs in. I verified I had all my tools and tried to start it. At first nothing because the battery is dead.. this is frustrating because it has been unhooked for the length of the project. I hook another battery up and try and start. The engine just spins and spins… Nothing does not even try and start. I thought I heard a slight backfire…. Nevertheless, nothing. I hit the ignition to stop the starter from overheating. I quickly took the valve cover off and could not see anything out of the norm. The chain was tight and everything seemed to be where it needed to be. So I took to turning the motor over by hand again just like the first time really easy then tough for a brief min and so on and so on. I took a look online and could find nothing that fit the bill so thus this long post. I did rotate the motor back around and put the cam locking tools back on just to ensure that had not skipped timing…. My gut tells me this is the only thing I could have messed up. The tools go on without an issue, I verified that the numbers are face up on the cams and that all three parts of the tool line up and bolt down. When the car turns over it spins just fine. There is no catch or horrible sounds like valves hitting.. it just spins.

when I figure out how to add pics/vids I will put those up here as well

Other thins I have checked….

Every fuse on the car

I Googled this problem so hard I ended up on page 5 of google results.

I have the Chilton’s manual and went through that.

I really hope someone out there has dealt with this before and can tell me a way to ensure that I have the timing correct and if I do what the heck is wrong. Car ran great up until I took it apart

Thanks for reading!!

#3

I've read that the flywheel might have more than one location for the locking tool. The correct one has all 4 pistons at the same height in their cylinder. Can be checked with a long, skinny rod in the spark plug hole, as a depth gauge.

I used the Bentley manual, not Chilton's, so can't comment on what tools were specified. Setting chain tension correctly is critical too. Turning the engine over by hand needs to be done CW only. Not sure what, if any, damage CCW rotation causes.

Maybe try a search on this forum for someone else's experience.

I used the Bentley manual, not Chilton's, so can't comment on what tools were specified. Setting chain tension correctly is critical too. Turning the engine over by hand needs to be done CW only. Not sure what, if any, damage CCW rotation causes.

Maybe try a search on this forum for someone else's experience.

#4

Still broke...

No Fabtex I still have not resolved this issue. Today I had to work on another vehicle so I was unable to get to it. I hope to soon my wife really wants her baby back.

Oldbrokenwind The Chilton manual only gave one location for the flywheel locking. However, it did not say anything about setting the chain tension… I did what made the most sense to me for this step. I made sure that the chain across the top was tight and then put in the chain

tensioner and went from there. I did only rotate the engine clock wise.. the only time I might have gone CCW was to back it up just a little when first installing the cam locking tools…The engine does sound a little odd when turning over. Almost like, there is no compression in the motor. I am not sure what the engine is supposed to sound like when it just turns over, as the car has always started just fine. IF I were off on my timing, would it not sound like a thrash machine and lots of metal on metal sound due to valves and pistons slapping? There is no metal on metal sound… it just cranks and cranks……and cranks some more. BTW I am getting no codes from the ECM except the Mass air flow sensor which I have unplugged. I will pull everything down again go with what you said about the pistons… are you saying that all pistons should be equal.. Not sure I understand what you mean however. Should 1 and 4 be the same and 2 and 3 be the same? Or will all four really be at the same height?

Thank you both for your help.

Oldbrokenwind The Chilton manual only gave one location for the flywheel locking. However, it did not say anything about setting the chain tension… I did what made the most sense to me for this step. I made sure that the chain across the top was tight and then put in the chain

tensioner and went from there. I did only rotate the engine clock wise.. the only time I might have gone CCW was to back it up just a little when first installing the cam locking tools…The engine does sound a little odd when turning over. Almost like, there is no compression in the motor. I am not sure what the engine is supposed to sound like when it just turns over, as the car has always started just fine. IF I were off on my timing, would it not sound like a thrash machine and lots of metal on metal sound due to valves and pistons slapping? There is no metal on metal sound… it just cranks and cranks……and cranks some more. BTW I am getting no codes from the ECM except the Mass air flow sensor which I have unplugged. I will pull everything down again go with what you said about the pistons… are you saying that all pistons should be equal.. Not sure I understand what you mean however. Should 1 and 4 be the same and 2 and 3 be the same? Or will all four really be at the same height?

Thank you both for your help.

#6

Let me start this with a disclaimer —- I’m a dedicated “shade-tree mechanic”, no professional car experience, and have only been working my Mini for 4 years. Anything I contribute to this forum is based on experience with my own Mini.

My timing chain / guides were dealer-replaced 2 - 3 years ago —- had the “death rattle”. As a result of adding mods, I decided to upgrade engine internals myself, to handle excess HP / torque. This is where my Mini timing experience comes from —- putting everything back together. As a side note, there were a few pieces of broken guide in the oil pan and the oil pump inlet screen —- dealer mechanic didn’t clean it all out. So, if you had a damaged chain guide, look for pieces in the oil pan and pump screen.

From your input, the Chilton manual should be shelved. Find a Bentley manual, either on-line or a local, large bookstore. It will have all the necessary torque settings, special tool reqmts, which bolts are “Torque To Yield” (aka stretch), and instructions for most any repair. The following instructions will be a summary, not detailed —- I don’t want any copyright infringement issues.

Special tools req’d:

Crank lock

Cam lock pair

Chain tension preload

for the angle indicator, I used a “calibrated eyeball” on my torque wrench handle

Since you say the engine turns easily, it’s probably timed close enough so there’s no valve / piston interference. Start by locking the crankshaft with the special tool. Observe the cam writing to ensure you’re close to the correct position, not 180 out. Remember, the crank turns twice for each cam rev. Verify by checking piston height in each cylinder. All 4 should be the same, within ¼ “ or so (contoured piston domes make measurement difficult). And FYI, this position is NOT TDC as in older engine timing. I’m pretty sure it’s #1 at 90 deg BTDC.

Loosen both cam chain sprockets so the cams can be positioned by the cam locking tools, and NOT move the crank. Install the cam locking tools. One thing I don’t remember is how much adjustment / rotation is available when mounting the sprockets / Vanos on the cam. It may be necessary to remove and re-position the sprocket. Do this one cam at a time, and maybe with another hand or two helping keep the chain from falling off the crank sprocket.

Remove the chain tensioner and install the timing chain tension adjustment tool —- used to pre-tension the chain BEFORE the cam sprockets are tightened. Adjust the tool as spec’d in the manual. Then, using NEW bolts, tighten the cam sprockets. I believe this process is used to ensure there is NO chain slack between ANY of the sprockets.

Re-install the chain tensioner, remove all the locking tools, and re-assemble. Bentley also recommends using silicon sealant on specific areas of the valve cover, to minimize leakage.

Another side note —- when the start button is pushed, the engine will crank for 15 - 20 seconds, then stop by itself IF it doesn’t start.

Let us know whether or not this helps. And, if anyone else has input / critique, jump in! I’m confident the process I used was OK, ‘cause my dyno results last month were over 300 WHP and torque. I did something right!

My timing chain / guides were dealer-replaced 2 - 3 years ago —- had the “death rattle”. As a result of adding mods, I decided to upgrade engine internals myself, to handle excess HP / torque. This is where my Mini timing experience comes from —- putting everything back together. As a side note, there were a few pieces of broken guide in the oil pan and the oil pump inlet screen —- dealer mechanic didn’t clean it all out. So, if you had a damaged chain guide, look for pieces in the oil pan and pump screen.

From your input, the Chilton manual should be shelved. Find a Bentley manual, either on-line or a local, large bookstore. It will have all the necessary torque settings, special tool reqmts, which bolts are “Torque To Yield” (aka stretch), and instructions for most any repair. The following instructions will be a summary, not detailed —- I don’t want any copyright infringement issues.

Special tools req’d:

Crank lock

Cam lock pair

Chain tension preload

for the angle indicator, I used a “calibrated eyeball” on my torque wrench handle

Since you say the engine turns easily, it’s probably timed close enough so there’s no valve / piston interference. Start by locking the crankshaft with the special tool. Observe the cam writing to ensure you’re close to the correct position, not 180 out. Remember, the crank turns twice for each cam rev. Verify by checking piston height in each cylinder. All 4 should be the same, within ¼ “ or so (contoured piston domes make measurement difficult). And FYI, this position is NOT TDC as in older engine timing. I’m pretty sure it’s #1 at 90 deg BTDC.

Loosen both cam chain sprockets so the cams can be positioned by the cam locking tools, and NOT move the crank. Install the cam locking tools. One thing I don’t remember is how much adjustment / rotation is available when mounting the sprockets / Vanos on the cam. It may be necessary to remove and re-position the sprocket. Do this one cam at a time, and maybe with another hand or two helping keep the chain from falling off the crank sprocket.

Remove the chain tensioner and install the timing chain tension adjustment tool —- used to pre-tension the chain BEFORE the cam sprockets are tightened. Adjust the tool as spec’d in the manual. Then, using NEW bolts, tighten the cam sprockets. I believe this process is used to ensure there is NO chain slack between ANY of the sprockets.

Re-install the chain tensioner, remove all the locking tools, and re-assemble. Bentley also recommends using silicon sealant on specific areas of the valve cover, to minimize leakage.

Another side note —- when the start button is pushed, the engine will crank for 15 - 20 seconds, then stop by itself IF it doesn’t start.

Let us know whether or not this helps. And, if anyone else has input / critique, jump in! I’m confident the process I used was OK, ‘cause my dyno results last month were over 300 WHP and torque. I did something right!

#7

Trending Topics

#9

Join Date: Jun 2012

Location: Northern California Bay Area

Posts: 182

Likes: 0

Received 8 Likes

on

7 Posts

no pretensioner

Let me start this with a disclaimer —- I’m a dedicated “shade-tree mechanic”, no professional car experience, and have only been working my Mini for 4 years. Anything I contribute to this forum is based on experience with my own Mini.

My timing chain / guides were dealer-replaced 2 - 3 years ago —- had the “death rattle”. As a result of adding mods, I decided to upgrade engine internals myself, to handle excess HP / torque. This is where my Mini timing experience comes from —- putting everything back together. As a side note, there were a few pieces of broken guide in the oil pan and the oil pump inlet screen —- dealer mechanic didn’t clean it all out. So, if you had a damaged chain guide, look for pieces in the oil pan and pump screen.

From your input, the Chilton manual should be shelved. Find a Bentley manual, either on-line or a local, large bookstore. It will have all the necessary torque settings, special tool reqmts, which bolts are “Torque To Yield” (aka stretch), and instructions for most any repair. The following instructions will be a summary, not detailed —- I don’t want any copyright infringement issues.

Special tools req’d:

Crank lock

Cam lock pair

Chain tension preload

for the angle indicator, I used a “calibrated eyeball” on my torque wrench handle

Since you say the engine turns easily, it’s probably timed close enough so there’s no valve / piston interference. Start by locking the crankshaft with the special tool. Observe the cam writing to ensure you’re close to the correct position, not 180 out. Remember, the crank turns twice for each cam rev. Verify by checking piston height in each cylinder. All 4 should be the same, within ¼ “ or so (contoured piston domes make measurement difficult). And FYI, this position is NOT TDC as in older engine timing. I’m pretty sure it’s #1 at 90 deg BTDC.

Loosen both cam chain sprockets so the cams can be positioned by the cam locking tools, and NOT move the crank. Install the cam locking tools. One thing I don’t remember is how much adjustment / rotation is available when mounting the sprockets / Vanos on the cam. It may be necessary to remove and re-position the sprocket. Do this one cam at a time, and maybe with another hand or two helping keep the chain from falling off the crank sprocket.

Remove the chain tensioner and install the timing chain tension adjustment tool —- used to pre-tension the chain BEFORE the cam sprockets are tightened. Adjust the tool as spec’d in the manual. Then, using NEW bolts, tighten the cam sprockets. I believe this process is used to ensure there is NO chain slack between ANY of the sprockets.

Re-install the chain tensioner, remove all the locking tools, and re-assemble. Bentley also recommends using silicon sealant on specific areas of the valve cover, to minimize leakage.

Another side note —- when the start button is pushed, the engine will crank for 15 - 20 seconds, then stop by itself IF it doesn’t start.

Let us know whether or not this helps. And, if anyone else has input / critique, jump in! I’m confident the process I used was OK, ‘cause my dyno results last month were over 300 WHP and torque. I did something right!

My timing chain / guides were dealer-replaced 2 - 3 years ago —- had the “death rattle”. As a result of adding mods, I decided to upgrade engine internals myself, to handle excess HP / torque. This is where my Mini timing experience comes from —- putting everything back together. As a side note, there were a few pieces of broken guide in the oil pan and the oil pump inlet screen —- dealer mechanic didn’t clean it all out. So, if you had a damaged chain guide, look for pieces in the oil pan and pump screen.

From your input, the Chilton manual should be shelved. Find a Bentley manual, either on-line or a local, large bookstore. It will have all the necessary torque settings, special tool reqmts, which bolts are “Torque To Yield” (aka stretch), and instructions for most any repair. The following instructions will be a summary, not detailed —- I don’t want any copyright infringement issues.

Special tools req’d:

Crank lock

Cam lock pair

Chain tension preload

for the angle indicator, I used a “calibrated eyeball” on my torque wrench handle

Since you say the engine turns easily, it’s probably timed close enough so there’s no valve / piston interference. Start by locking the crankshaft with the special tool. Observe the cam writing to ensure you’re close to the correct position, not 180 out. Remember, the crank turns twice for each cam rev. Verify by checking piston height in each cylinder. All 4 should be the same, within ¼ “ or so (contoured piston domes make measurement difficult). And FYI, this position is NOT TDC as in older engine timing. I’m pretty sure it’s #1 at 90 deg BTDC.

Loosen both cam chain sprockets so the cams can be positioned by the cam locking tools, and NOT move the crank. Install the cam locking tools. One thing I don’t remember is how much adjustment / rotation is available when mounting the sprockets / Vanos on the cam. It may be necessary to remove and re-position the sprocket. Do this one cam at a time, and maybe with another hand or two helping keep the chain from falling off the crank sprocket.

Remove the chain tensioner and install the timing chain tension adjustment tool —- used to pre-tension the chain BEFORE the cam sprockets are tightened. Adjust the tool as spec’d in the manual. Then, using NEW bolts, tighten the cam sprockets. I believe this process is used to ensure there is NO chain slack between ANY of the sprockets.

Re-install the chain tensioner, remove all the locking tools, and re-assemble. Bentley also recommends using silicon sealant on specific areas of the valve cover, to minimize leakage.

Another side note —- when the start button is pushed, the engine will crank for 15 - 20 seconds, then stop by itself IF it doesn’t start.

Let us know whether or not this helps. And, if anyone else has input / critique, jump in! I’m confident the process I used was OK, ‘cause my dyno results last month were over 300 WHP and torque. I did something right!

#10

You might get lucky and remove enough slack, but that's not a gamble I'm willing to take --- engine timing is too critical to get it wrong.

#11

#12

#14

R56/N14 No start after Timinng chain install

On installation, crank bolt, both cam sprocket bolts have to be loose. And tensioner removed. Only one hole in the flywheel for the pin to go into. Install the pin. Install the cam hold tools with the cam letters pointing up. Install the tensioner. Tighten the cam bolts and crank bolt. Install the the other parts removed. Don't forget the ground for the coils. Start the car. Tensioner must be installed before all three bolts are tightened or it will most likely be a tooth off by time all the slack gets were it wants to be from cranking it over.

#15

Sprintcars,

Thanks for the info. I have a question regarding the "hole" in the flywheel.... when I place the pin thru the bellhousing and into the flywheel, and I check the heights of the pistons, they all seem to be at the same heights, thus, they must not be at TDC, have you seen this before?

Thanks for the info. I have a question regarding the "hole" in the flywheel.... when I place the pin thru the bellhousing and into the flywheel, and I check the heights of the pistons, they all seem to be at the same heights, thus, they must not be at TDC, have you seen this before?

#16

R56/N14 No start after Timinng chain install

Originally Posted by 09R56

Sprintcars,

Thanks for the info. I have a question regarding the "hole" in the flywheel.... when I place the pin thru the bellhousing and into the flywheel, and I check the heights of the pistons, they all seem to be at the same heights, thus, they must not be at TDC, have you seen this before?

Thanks for the info. I have a question regarding the "hole" in the flywheel.... when I place the pin thru the bellhousing and into the flywheel, and I check the heights of the pistons, they all seem to be at the same heights, thus, they must not be at TDC, have you seen this before?

Now that the pin is in, if the cams are installed, try installing the cam tools. Should drop on or having very light taps with a hammer. If they don't go on, loosen the balancer center bolt and the two cam sprocket bolts. Take out the tensioner. Align the cams letters up and install cam tools. Install tensioner. Tighten the balancer and cam sprocket bolts. Finish the rest of the job. Start it. If you don't install that tensioner before the bolts are tightened, ANY OF THEM, slack in the chain can get caught somewhere in that chain. When you crank it. Slack comes out. Cam timing is off. Car won't start. AGAIN !! If that happens, do it all again.

And those bolts are a torque yield bolt. I have torqued them a second time, I only recommend that if you have a good feel with a torque wrench

#17

Much appreciate the fast response and help man!!!!!

So long story short, I ended up timing the engine based on finding out where the pistons are with respect to the camshafts after installing the locking tool, then placed back the sprockets, and new tensioner on then tried to rotate the motor with a ratchet and noticed that everything is rotating ok until I felt some resistance. Mind u the reason why I am having to do this job is because the chain guard had been broken and came to find out it had jumped a tooth or two…not sure how much!

So while turning the crank manually, I felt some resistance then looked thru the chain and noticed some plastic debree was stuck on the crank sprocket. Therefore, I will need to redo all the timing again once I open up the crank sprocket and clean it off.

The questions that I have now, is how would you approach taking the crank sprocket off? Do u lock the flywheel in place with the locking pin, unbolt the crank pulley & sprocket, clean it out, then re-torque the crank sprocket/pulley back into place while the pin holding the flywheel?

Its time consuming but I think I have a pretty good hang of the job after reading all the good posts around here (Thank you!). And yes I have new hardware/bolts for the sprockets, however, I am planning on using them last once I build some compression after this job is done as I am testing it with a compression tester. This is more or less the first go at it so I didn’t want to use the new hardware

Thanks again for the help!

So long story short, I ended up timing the engine based on finding out where the pistons are with respect to the camshafts after installing the locking tool, then placed back the sprockets, and new tensioner on then tried to rotate the motor with a ratchet and noticed that everything is rotating ok until I felt some resistance. Mind u the reason why I am having to do this job is because the chain guard had been broken and came to find out it had jumped a tooth or two…not sure how much!

So while turning the crank manually, I felt some resistance then looked thru the chain and noticed some plastic debree was stuck on the crank sprocket. Therefore, I will need to redo all the timing again once I open up the crank sprocket and clean it off.

The questions that I have now, is how would you approach taking the crank sprocket off? Do u lock the flywheel in place with the locking pin, unbolt the crank pulley & sprocket, clean it out, then re-torque the crank sprocket/pulley back into place while the pin holding the flywheel?

Its time consuming but I think I have a pretty good hang of the job after reading all the good posts around here (Thank you!). And yes I have new hardware/bolts for the sprockets, however, I am planning on using them last once I build some compression after this job is done as I am testing it with a compression tester. This is more or less the first go at it so I didn’t want to use the new hardware

Thanks again for the help!

#18

R56/N14 No start after Timinng chain install

Originally Posted by 09R56

Much appreciate the fast response and help man!!!!!

So long story short, I ended up timing the engine based on finding out where the pistons are with respect to the camshafts after installing the locking tool, then placed back the sprockets, and new tensioner on then tried to rotate the motor with a ratchet and noticed that everything is rotating ok until I felt some resistance. Mind u the reason why I am having to do this job is because the chain guard had been broken and came to find out it had jumped a tooth or two…not sure how much!

So while turning the crank manually, I felt some resistance then looked thru the chain and noticed some plastic debree was stuck on the crank sprocket. Therefore, I will need to redo all the timing again once I open up the crank sprocket and clean it off.

The questions that I have now, is how would you approach taking the crank sprocket off? Do u lock the flywheel in place with the locking pin, unbolt the crank pulley & sprocket, clean it out, then re-torque the crank sprocket/pulley back into place while the pin holding the flywheel?

Its time consuming but I think I have a pretty good hang of the job after reading all the good posts around here (Thank you!). And yes I have new hardware/bolts for the sprockets, however, I am planning on using them last once I build some compression after this job is done as I am testing it with a compression tester. This is more or less the first go at it so I didn’t want to use the new hardware

Thanks again for the help!

So long story short, I ended up timing the engine based on finding out where the pistons are with respect to the camshafts after installing the locking tool, then placed back the sprockets, and new tensioner on then tried to rotate the motor with a ratchet and noticed that everything is rotating ok until I felt some resistance. Mind u the reason why I am having to do this job is because the chain guard had been broken and came to find out it had jumped a tooth or two…not sure how much!

So while turning the crank manually, I felt some resistance then looked thru the chain and noticed some plastic debree was stuck on the crank sprocket. Therefore, I will need to redo all the timing again once I open up the crank sprocket and clean it off.

The questions that I have now, is how would you approach taking the crank sprocket off? Do u lock the flywheel in place with the locking pin, unbolt the crank pulley & sprocket, clean it out, then re-torque the crank sprocket/pulley back into place while the pin holding the flywheel?

Its time consuming but I think I have a pretty good hang of the job after reading all the good posts around here (Thank you!). And yes I have new hardware/bolts for the sprockets, however, I am planning on using them last once I build some compression after this job is done as I am testing it with a compression tester. This is more or less the first go at it so I didn’t want to use the new hardware

Thanks again for the help!

#19

#20

Yup, I agree! Planning on redoing it after i clean up the crank sprocket area. but what are your thoughts on my questions on how to remove the crank sprocket? am I in the ball park?

Thanks

"The questions that I have now, is how would you approach taking the crank sprocket off? Do u lock the flywheel in place with the locking pin, unbolt the crank pulley & sprocket, clean it out, then re-torque the crank sprocket/pulley back into place while the pin holding the flywheel?"

Thanks

"The questions that I have now, is how would you approach taking the crank sprocket off? Do u lock the flywheel in place with the locking pin, unbolt the crank pulley & sprocket, clean it out, then re-torque the crank sprocket/pulley back into place while the pin holding the flywheel?"

#23

#25

R56/N14 No start after Timinng chain install

That ain't good. Did you use thread locker/red Lock tite? Or the threads are gauled, maybe.

How tight did you make it ? Something is in them treads. Right now my eyes are really big.

Not saying it will. At all. But just a heads up. If that bolt don't come out. And The threads are messed up, you can't just buy another crank. The journals are not all the same.

How tight did you make it ? Something is in them treads. Right now my eyes are really big.

Not saying it will. At all. But just a heads up. If that bolt don't come out. And The threads are messed up, you can't just buy another crank. The journals are not all the same.