R56 N18 Valve Stem Seals / Inlet Camshaft

#1

N18 Valve Stem Seals / Inlet Camshaft

Hello. Looking to replace the valve stem seals on my 2011 R56 with N18 engine.

Do I absolutely need the special tool to remove the valvetronic / retainer springs above the intake camshaft? Or Can it be done by hand?

Can I remove the intake camshaft and valvetronic spring (and their brackets) all together, or do I have to remove springs and brackets one by one?

Thank you.

Do I absolutely need the special tool to remove the valvetronic / retainer springs above the intake camshaft? Or Can it be done by hand?

Can I remove the intake camshaft and valvetronic spring (and their brackets) all together, or do I have to remove springs and brackets one by one?

Thank you.

#2

6th Gear

iTrader: (4)

In my experience, you do not need the special tool. I used a pair of needle-nose vise-grips. You have to "unload" the springs from the rockers before removing the blocks, then the cam. I put the springs back with the same method. You do need to ensure they they go back on the rockers correctly. They fit into a little notch, as I remember.

#4

#5

Hi I did the job with the special tools. here is the thread showing the tools

https://www.northamericanmotoring.co...l-replace.html

https://www.northamericanmotoring.co...l-replace.html

The following users liked this post:

65calinete (05-31-2021)

#6

Oh man you're in for a treat! It took me about 20 hours over a few evenings (a couple mechanics also quoted me 20 hours). Disassembly up to the point of replacing the valve seals is pretty straight forward. The hardest part for me was putting back the tiny keepers that hold the springs on top of each valve. Second hardest was putting back the intermediate springs (videos above). Maintaining timing is the least of your worries because you must use the N18 timing tool.

This job is very similar to the timing chain replacement job with regards to initial disassembly and final assembly. Plenty of videos out there to use as a guide. It's very similar to the N14 with the exception of the exhaust camshaft having a VANOS gear but that doesn't change anything.

Essential tools: Ratchet & socket set (preferably slim profile ratchet or pass-thru), N18 timing tool, overhead camshaft valve spring compressor, torque wrench, magnet with long reach, lots of clean shop towels and cotton *****.

Here are the steps as best as I can remember:

- Remove ignition coils, spark plugs, valve cover, intake air box. Torque setting for valve cover bolts is 10nm.

- Rotate engine at the crankshaft until both intake and exhaust camshafts have the text engraving facing upwards.

- Place timing locking tool on the camshafts. No need to use the crankshaft/flywheel locking pin at this point.

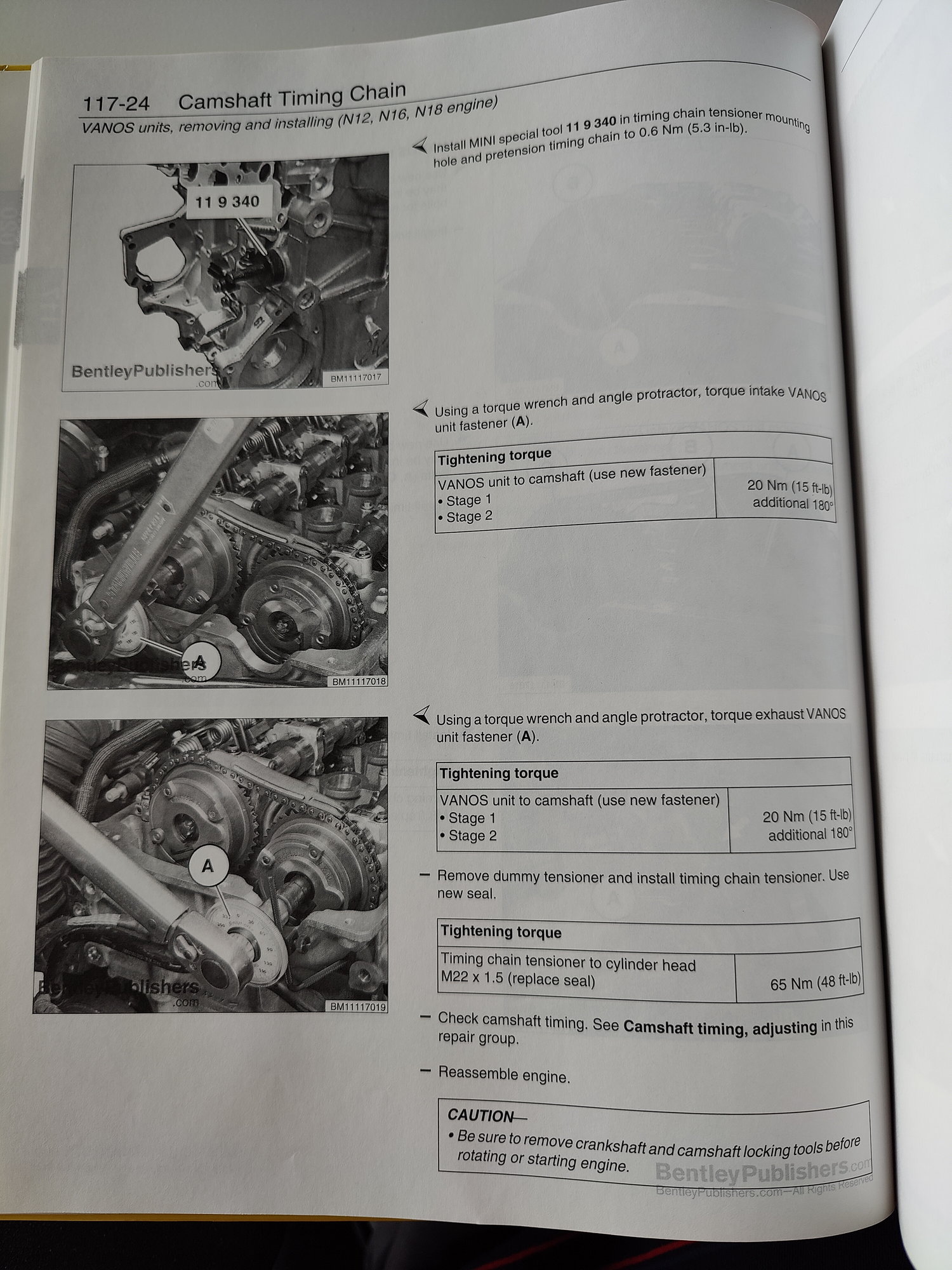

- Remove timing chain tensioner. You'll need a 27mm thin wall socket. If a thin wall socket is unavailable, you'll need to remove the intake solenoid to make space. Torque setting for tensioner is either 65nm or 80nm (two different sources). I went for 75nm during reassembly.

- Remove chain plastic guide at the top. Torque setting for the two bolts is 20nm. I did 10nm then tightened slightly by hand.

- Remove the bolts holding the VANOS sprockets/gears to the camshafts. Slide the sprockets/gears out. It's okay if the chain falls down the engine, you can always pull it up with a magnet. The bolt on the exhaust side might be hard to get a socket on it because the engine mount bracket is in the way. Hence my recommendation for slim profile or pass-thru ratchet. Or just remove the mounting bracket (a tiny bit extra work if tools are not available).

- Next step is to unload the intermediate springs on the intake camshaft. I used a thin plastic rope to pull the spring arms away from the rockers, then moved the spring arms to the side to rest on the intake camshaft. Check videos above for other ways.

- Now remove the exhaust and intake camshafts, and also remove the VANOS/VVT secondary camshaft that's under the primary intake camshaft. It is very important that you keep everything in order. Every part and bolt must go back to where they came from. Torque setting for bolts holding the camshafts is 10nm.

- At this point you will want to block all openings leading to inside/bottom of engine. Use the cotton ***** on the surface of all openings, do not push down. This is a precautionary step to avoid small parts fallings inside the engine.

- Next is to prep for valve spring removal. Some people use compressed air into cylinder to prevent valve dropping inside when spring is removed. I used the rope method which is shoving a thin plastic rope down the spark plug holes, then rotate the engine at the crankshaft until the piston compresses the rope against the valves in the cylinder I was working on. Worked fine for me, just time consuming. Have to repeat for each cylinder. If using air, crankshaft/flywheel locking pin must be in place.

- Once a cylinder is compressed with rope, use the valve spring compressor tool to compress the valve springs. Use a magnet to pull out the two little keepers per valve.

- Pull the valve seal out with needle nose pliers and replace with new.

- Put the spring back in place, compress it, and put the two tiny keepers in their place. This was the hardest part for me because I had one hand compressing the spring and the other trying to place those small pieces. It's really hard to put them back in place because of the tight areas. I found the best way to put them back is to use a little piece of sticky tack on an end of a thin wooden skewer. Stick the keeper to the sticky part and feed it down to its location. Release valve spring compressor after keepers are in place.

- Once done with 4 valves / 1 cylinder, remove the rope and repeat for next cylinder.

- Reassemble in same order of disassembly.

- Note that when reassembling the intake camshaft and associated intermediate springs, a lot of force will be needed to pull back the spring arms to place them on the rockers.

- Once camshafts are back in place, assembly is very similar to the timing chain job. Note that there was never a need to remove the pulley and crank hub where the chain connects to on the bottom of the engine.

Hope this helps and good luck!

This job is very similar to the timing chain replacement job with regards to initial disassembly and final assembly. Plenty of videos out there to use as a guide. It's very similar to the N14 with the exception of the exhaust camshaft having a VANOS gear but that doesn't change anything.

Essential tools: Ratchet & socket set (preferably slim profile ratchet or pass-thru), N18 timing tool, overhead camshaft valve spring compressor, torque wrench, magnet with long reach, lots of clean shop towels and cotton *****.

Here are the steps as best as I can remember:

- Remove ignition coils, spark plugs, valve cover, intake air box. Torque setting for valve cover bolts is 10nm.

- Rotate engine at the crankshaft until both intake and exhaust camshafts have the text engraving facing upwards.

- Place timing locking tool on the camshafts. No need to use the crankshaft/flywheel locking pin at this point.

- Remove timing chain tensioner. You'll need a 27mm thin wall socket. If a thin wall socket is unavailable, you'll need to remove the intake solenoid to make space. Torque setting for tensioner is either 65nm or 80nm (two different sources). I went for 75nm during reassembly.

- Remove chain plastic guide at the top. Torque setting for the two bolts is 20nm. I did 10nm then tightened slightly by hand.

- Remove the bolts holding the VANOS sprockets/gears to the camshafts. Slide the sprockets/gears out. It's okay if the chain falls down the engine, you can always pull it up with a magnet. The bolt on the exhaust side might be hard to get a socket on it because the engine mount bracket is in the way. Hence my recommendation for slim profile or pass-thru ratchet. Or just remove the mounting bracket (a tiny bit extra work if tools are not available).

- Next step is to unload the intermediate springs on the intake camshaft. I used a thin plastic rope to pull the spring arms away from the rockers, then moved the spring arms to the side to rest on the intake camshaft. Check videos above for other ways.

- Now remove the exhaust and intake camshafts, and also remove the VANOS/VVT secondary camshaft that's under the primary intake camshaft. It is very important that you keep everything in order. Every part and bolt must go back to where they came from. Torque setting for bolts holding the camshafts is 10nm.

- At this point you will want to block all openings leading to inside/bottom of engine. Use the cotton ***** on the surface of all openings, do not push down. This is a precautionary step to avoid small parts fallings inside the engine.

- Next is to prep for valve spring removal. Some people use compressed air into cylinder to prevent valve dropping inside when spring is removed. I used the rope method which is shoving a thin plastic rope down the spark plug holes, then rotate the engine at the crankshaft until the piston compresses the rope against the valves in the cylinder I was working on. Worked fine for me, just time consuming. Have to repeat for each cylinder. If using air, crankshaft/flywheel locking pin must be in place.

- Once a cylinder is compressed with rope, use the valve spring compressor tool to compress the valve springs. Use a magnet to pull out the two little keepers per valve.

- Pull the valve seal out with needle nose pliers and replace with new.

- Put the spring back in place, compress it, and put the two tiny keepers in their place. This was the hardest part for me because I had one hand compressing the spring and the other trying to place those small pieces. It's really hard to put them back in place because of the tight areas. I found the best way to put them back is to use a little piece of sticky tack on an end of a thin wooden skewer. Stick the keeper to the sticky part and feed it down to its location. Release valve spring compressor after keepers are in place.

- Once done with 4 valves / 1 cylinder, remove the rope and repeat for next cylinder.

- Reassemble in same order of disassembly.

- Note that when reassembling the intake camshaft and associated intermediate springs, a lot of force will be needed to pull back the spring arms to place them on the rockers.

- Once camshafts are back in place, assembly is very similar to the timing chain job. Note that there was never a need to remove the pulley and crank hub where the chain connects to on the bottom of the engine.

Hope this helps and good luck!

Last edited by Nader230; 05-26-2021 at 02:08 PM.

The following 3 users liked this post by Nader230:

#7

Trending Topics

#8

Thanks!

Oh man you're in for a treat! It took me about 20 hours over a few evenings (a couple mechanics also quoted me 20 hours). Disassembly up to the point of replacing the valve seals is pretty straight forward. The hardest part for me was putting back the tiny keepers that hold the springs on top of each valve. Second hardest was putting back the intermediate springs (videos above). Maintaining timing is the least of your worries because you must use the N18 timing tool.

This job is very similar to the timing chain replacement job with regards to initial disassembly and final assembly. Plenty of videos out there to use as a guide. It's very similar to the N14 with the exception of the exhaust camshaft having a VANOS gear but that doesn't change anything.

Essential tools: Ratchet & socket set (preferably slim profile ratchet or pass-thru), N18 timing tool, overhead camshaft valve spring compressor, torque wrench, magnet with long reach, lots of clean shop towels and cotton *****.

Here are the steps as best as I can remember:

- Remove ignition coils, spark plugs, valve cover, intake air box. Torque setting for valve cover bolts is 10nm.

- Rotate engine at the crankshaft until both intake and exhaust camshafts have the text engraving facing upwards.

- Place timing locking tool on the camshafts. No need to use the crankshaft/flywheel locking pin at this point.

- Remove timing chain tensioner. You'll need a 27mm thin wall socket. If a thin wall socket is unavailable, you'll need to remove the intake solenoid to make space. Torque setting for tensioner is either 65nm or 80nm (two different sources). I went for 75nm during reassembly.

- Remove chain plastic guide at the top. Torque setting for the two bolts is 20nm. I did 10nm then tightened slightly by hand.

- Remove the bolts holding the VANOS sprockets/gears to the camshafts. Slide the sprockets/gears out. It's okay if the chain falls down the engine, you can always pull it up with a magnet. The bolt on the exhaust side might be hard to get a socket on it because the engine mount bracket is in the way. Hence my recommendation for slim profile or pass-thru ratchet. Or just remove the mounting bracket (a tiny bit extra work if tools are not available).

- Next step is to unload the intermediate springs on the intake camshaft. I used a thin plastic rope to pull the spring arms away from the rockers, then moved the spring arms to the side to rest on the intake camshaft. Check videos above for other ways.

- Now remove the exhaust and intake camshafts, and also remove the VANOS/VVT secondary camshaft that's under the primary intake camshaft. It is very important that you keep everything in order. Every part and bolt must go back to where they came from. Torque setting for bolts holding the camshafts is 10nm.

- At this point you will want to block all openings leading to inside/bottom of engine. Use the cotton ***** on the surface of all openings, do not push down. This is a precautionary step to avoid small parts fallings inside the engine.

- Next is to prep for valve spring removal. Some people use compressed air into cylinder to prevent valve dropping inside when spring is removed. I used the rope method which is shoving a thin plastic rope down the spark plug holes, then rotate the engine at the crankshaft until the piston compresses the rope against the valves in the cylinder I was working on. Worked fine for me, just time consuming. Have to repeat for each cylinder. If using air, crankshaft/flywheel locking pin must be in place.

- Once a cylinder is compressed with rope, use the valve spring compressor tool to compress the valve springs. Use a magnet to pull out the two little keepers per valve.

- Pull the valve seal out with needle nose pliers and replace with new.

- Put the spring back in place, compress it, and put the two tiny keepers in their place. This was the hardest part for me because I had one hand compressing the spring and the other trying to place those small pieces. It's really hard to put them back in place because of the tight areas. I found the best way to put them back is to use a little piece of sticky tack on an end of a thin wooden skewer. Stick the keeper to the sticky part and feed it down to its location. Release valve spring compressor after keepers are in place.

- Once done with 4 valves / 1 cylinder, remove the rope and repeat for next cylinder.

- Reassemble in same order of disassembly.

- Note that when reassembling the intake camshaft and associated intermediate springs, a lot of force will be needed to pull back the spring arms to place them on the rockers.

- Once camshafts are back in place, assembly is very similar to the timing chain job. Note that there was never a need to remove the pulley and crank hub where the chain connects to on the bottom of the engine.

Hope this helps and good luck!

This job is very similar to the timing chain replacement job with regards to initial disassembly and final assembly. Plenty of videos out there to use as a guide. It's very similar to the N14 with the exception of the exhaust camshaft having a VANOS gear but that doesn't change anything.

Essential tools: Ratchet & socket set (preferably slim profile ratchet or pass-thru), N18 timing tool, overhead camshaft valve spring compressor, torque wrench, magnet with long reach, lots of clean shop towels and cotton *****.

Here are the steps as best as I can remember:

- Remove ignition coils, spark plugs, valve cover, intake air box. Torque setting for valve cover bolts is 10nm.

- Rotate engine at the crankshaft until both intake and exhaust camshafts have the text engraving facing upwards.

- Place timing locking tool on the camshafts. No need to use the crankshaft/flywheel locking pin at this point.

- Remove timing chain tensioner. You'll need a 27mm thin wall socket. If a thin wall socket is unavailable, you'll need to remove the intake solenoid to make space. Torque setting for tensioner is either 65nm or 80nm (two different sources). I went for 75nm during reassembly.

- Remove chain plastic guide at the top. Torque setting for the two bolts is 20nm. I did 10nm then tightened slightly by hand.

- Remove the bolts holding the VANOS sprockets/gears to the camshafts. Slide the sprockets/gears out. It's okay if the chain falls down the engine, you can always pull it up with a magnet. The bolt on the exhaust side might be hard to get a socket on it because the engine mount bracket is in the way. Hence my recommendation for slim profile or pass-thru ratchet. Or just remove the mounting bracket (a tiny bit extra work if tools are not available).

- Next step is to unload the intermediate springs on the intake camshaft. I used a thin plastic rope to pull the spring arms away from the rockers, then moved the spring arms to the side to rest on the intake camshaft. Check videos above for other ways.

- Now remove the exhaust and intake camshafts, and also remove the VANOS/VVT secondary camshaft that's under the primary intake camshaft. It is very important that you keep everything in order. Every part and bolt must go back to where they came from. Torque setting for bolts holding the camshafts is 10nm.

- At this point you will want to block all openings leading to inside/bottom of engine. Use the cotton ***** on the surface of all openings, do not push down. This is a precautionary step to avoid small parts fallings inside the engine.

- Next is to prep for valve spring removal. Some people use compressed air into cylinder to prevent valve dropping inside when spring is removed. I used the rope method which is shoving a thin plastic rope down the spark plug holes, then rotate the engine at the crankshaft until the piston compresses the rope against the valves in the cylinder I was working on. Worked fine for me, just time consuming. Have to repeat for each cylinder. If using air, crankshaft/flywheel locking pin must be in place.

- Once a cylinder is compressed with rope, use the valve spring compressor tool to compress the valve springs. Use a magnet to pull out the two little keepers per valve.

- Pull the valve seal out with needle nose pliers and replace with new.

- Put the spring back in place, compress it, and put the two tiny keepers in their place. This was the hardest part for me because I had one hand compressing the spring and the other trying to place those small pieces. It's really hard to put them back in place because of the tight areas. I found the best way to put them back is to use a little piece of sticky tack on an end of a thin wooden skewer. Stick the keeper to the sticky part and feed it down to its location. Release valve spring compressor after keepers are in place.

- Once done with 4 valves / 1 cylinder, remove the rope and repeat for next cylinder.

- Reassemble in same order of disassembly.

- Note that when reassembling the intake camshaft and associated intermediate springs, a lot of force will be needed to pull back the spring arms to place them on the rockers.

- Once camshafts are back in place, assembly is very similar to the timing chain job. Note that there was never a need to remove the pulley and crank hub where the chain connects to on the bottom of the engine.

Hope this helps and good luck!

#9

Cam shafts

Oh man you're in for a treat! It took me about 20 hours over a few evenings (a couple mechanics also quoted me 20 hours). Disassembly up to the point of replacing the valve seals is pretty straight forward. The hardest part for me was putting back the tiny keepers that hold the springs on top of each valve. Second hardest was putting back the intermediate springs (videos above). Maintaining timing is the least of your worries because you must use the N18 timing tool.

This job is very similar to the timing chain replacement job with regards to initial disassembly and final assembly. Plenty of videos out there to use as a guide. It's very similar to the N14 with the exception of the exhaust camshaft having a VANOS gear but that doesn't change anything.

Essential tools: Ratchet & socket set (preferably slim profile ratchet or pass-thru), N18 timing tool, overhead camshaft valve spring compressor, torque wrench, magnet with long reach, lots of clean shop towels and cotton *****.

Here are the steps as best as I can remember:

- Remove ignition coils, spark plugs, valve cover, intake air box. Torque setting for valve cover bolts is 10nm.

- Rotate engine at the crankshaft until both intake and exhaust camshafts have the text engraving facing upwards.

- Place timing locking tool on the camshafts. No need to use the crankshaft/flywheel locking pin at this point.

- Remove timing chain tensioner. You'll need a 27mm thin wall socket. If a thin wall socket is unavailable, you'll need to remove the intake solenoid to make space. Torque setting for tensioner is either 65nm or 80nm (two different sources). I went for 75nm during reassembly.

- Remove chain plastic guide at the top. Torque setting for the two bolts is 20nm. I did 10nm then tightened slightly by hand.

- Remove the bolts holding the VANOS sprockets/gears to the camshafts. Slide the sprockets/gears out. It's okay if the chain falls down the engine, you can always pull it up with a magnet. The bolt on the exhaust side might be hard to get a socket on it because the engine mount bracket is in the way. Hence my recommendation for slim profile or pass-thru ratchet. Or just remove the mounting bracket (a tiny bit extra work if tools are not available).

- Next step is to unload the intermediate springs on the intake camshaft. I used a thin plastic rope to pull the spring arms away from the rockers, then moved the spring arms to the side to rest on the intake camshaft. Check videos above for other ways.

- Now remove the exhaust and intake camshafts, and also remove the VANOS/VVT secondary camshaft that's under the primary intake camshaft. It is very important that you keep everything in order. Every part and bolt must go back to where they came from. Torque setting for bolts holding the camshafts is 10nm.

- At this point you will want to block all openings leading to inside/bottom of engine. Use the cotton ***** on the surface of all openings, do not push down. This is a precautionary step to avoid small parts fallings inside the engine.

- Next is to prep for valve spring removal. Some people use compressed air into cylinder to prevent valve dropping inside when spring is removed. I used the rope method which is shoving a thin plastic rope down the spark plug holes, then rotate the engine at the crankshaft until the piston compresses the rope against the valves in the cylinder I was working on. Worked fine for me, just time consuming. Have to repeat for each cylinder. If using air, crankshaft/flywheel locking pin must be in place.

- Once a cylinder is compressed with rope, use the valve spring compressor tool to compress the valve springs. Use a magnet to pull out the two little keepers per valve.

- Pull the valve seal out with needle nose pliers and replace with new.

- Put the spring back in place, compress it, and put the two tiny keepers in their place. This was the hardest part for me because I had one hand compressing the spring and the other trying to place those small pieces. It's really hard to put them back in place because of the tight areas. I found the best way to put them back is to use a little piece of sticky tack on an end of a thin wooden skewer. Stick the keeper to the sticky part and feed it down to its location. Release valve spring compressor after keepers are in place.

- Once done with 4 valves / 1 cylinder, remove the rope and repeat for next cylinder.

- Reassemble in same order of disassembly.

- Note that when reassembling the intake camshaft and associated intermediate springs, a lot of force will be needed to pull back the spring arms to place them on the rockers.

- Once camshafts are back in place, assembly is very similar to the timing chain job. Note that there was never a need to remove the pulley and crank hub where the chain connects to on the bottom of the engine.

Hope this helps and good luck!

This job is very similar to the timing chain replacement job with regards to initial disassembly and final assembly. Plenty of videos out there to use as a guide. It's very similar to the N14 with the exception of the exhaust camshaft having a VANOS gear but that doesn't change anything.

Essential tools: Ratchet & socket set (preferably slim profile ratchet or pass-thru), N18 timing tool, overhead camshaft valve spring compressor, torque wrench, magnet with long reach, lots of clean shop towels and cotton *****.

Here are the steps as best as I can remember:

- Remove ignition coils, spark plugs, valve cover, intake air box. Torque setting for valve cover bolts is 10nm.

- Rotate engine at the crankshaft until both intake and exhaust camshafts have the text engraving facing upwards.

- Place timing locking tool on the camshafts. No need to use the crankshaft/flywheel locking pin at this point.

- Remove timing chain tensioner. You'll need a 27mm thin wall socket. If a thin wall socket is unavailable, you'll need to remove the intake solenoid to make space. Torque setting for tensioner is either 65nm or 80nm (two different sources). I went for 75nm during reassembly.

- Remove chain plastic guide at the top. Torque setting for the two bolts is 20nm. I did 10nm then tightened slightly by hand.

- Remove the bolts holding the VANOS sprockets/gears to the camshafts. Slide the sprockets/gears out. It's okay if the chain falls down the engine, you can always pull it up with a magnet. The bolt on the exhaust side might be hard to get a socket on it because the engine mount bracket is in the way. Hence my recommendation for slim profile or pass-thru ratchet. Or just remove the mounting bracket (a tiny bit extra work if tools are not available).

- Next step is to unload the intermediate springs on the intake camshaft. I used a thin plastic rope to pull the spring arms away from the rockers, then moved the spring arms to the side to rest on the intake camshaft. Check videos above for other ways.

- Now remove the exhaust and intake camshafts, and also remove the VANOS/VVT secondary camshaft that's under the primary intake camshaft. It is very important that you keep everything in order. Every part and bolt must go back to where they came from. Torque setting for bolts holding the camshafts is 10nm.

- At this point you will want to block all openings leading to inside/bottom of engine. Use the cotton ***** on the surface of all openings, do not push down. This is a precautionary step to avoid small parts fallings inside the engine.

- Next is to prep for valve spring removal. Some people use compressed air into cylinder to prevent valve dropping inside when spring is removed. I used the rope method which is shoving a thin plastic rope down the spark plug holes, then rotate the engine at the crankshaft until the piston compresses the rope against the valves in the cylinder I was working on. Worked fine for me, just time consuming. Have to repeat for each cylinder. If using air, crankshaft/flywheel locking pin must be in place.

- Once a cylinder is compressed with rope, use the valve spring compressor tool to compress the valve springs. Use a magnet to pull out the two little keepers per valve.

- Pull the valve seal out with needle nose pliers and replace with new.

- Put the spring back in place, compress it, and put the two tiny keepers in their place. This was the hardest part for me because I had one hand compressing the spring and the other trying to place those small pieces. It's really hard to put them back in place because of the tight areas. I found the best way to put them back is to use a little piece of sticky tack on an end of a thin wooden skewer. Stick the keeper to the sticky part and feed it down to its location. Release valve spring compressor after keepers are in place.

- Once done with 4 valves / 1 cylinder, remove the rope and repeat for next cylinder.

- Reassemble in same order of disassembly.

- Note that when reassembling the intake camshaft and associated intermediate springs, a lot of force will be needed to pull back the spring arms to place them on the rockers.

- Once camshafts are back in place, assembly is very similar to the timing chain job. Note that there was never a need to remove the pulley and crank hub where the chain connects to on the bottom of the engine.

Hope this helps and good luck!

#10

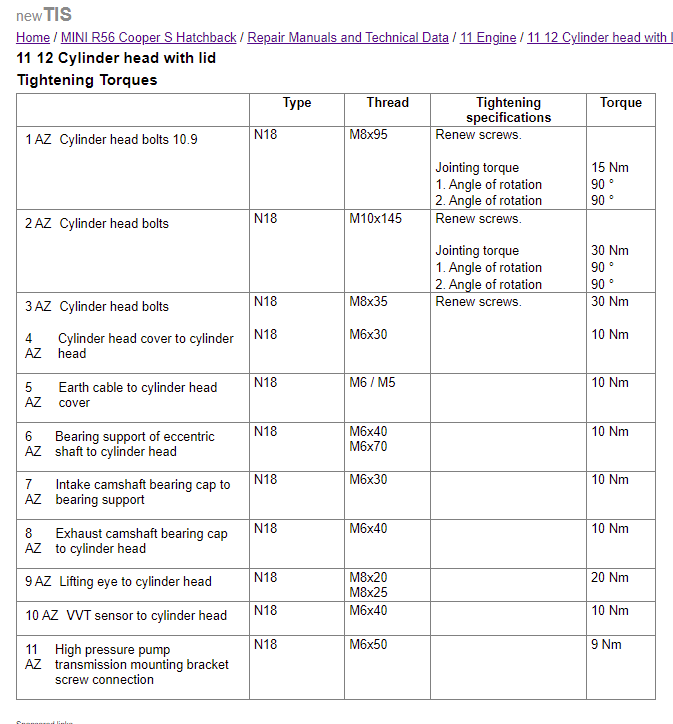

When reinstalling the intake and exhaust camshafts, yes you just lock them with the tool again. See attached images for more instructions.

#11

Also just a reminder to make sure the flywheel is locked with the locking pin that comes with the timing toolkit, before you lock the camshafts. That way your engine will be in-time; crankshaft, intake camshaft, exhaust camshaft.

#13

#14

I am doing this right now. I had to replace the head gasket too, so I'm doing it with the head off. Much easier to place the keepers with both hands and the ability to reposition the head!

Does anybody know the torque spec for the cam caps? They are not in the Bentley manual. I have found a couple of different answers for the n14, but nothing for an n18. There is a general torque spec chart in the Bentley, but I want to be sure I do this right.

thanks

Does anybody know the torque spec for the cam caps? They are not in the Bentley manual. I have found a couple of different answers for the n14, but nothing for an n18. There is a general torque spec chart in the Bentley, but I want to be sure I do this right.

thanks

Thread

Thread Starter

Forum

Replies

Last Post

Wanderlustsrt

Stock Problems/Issues

16

05-05-2017 09:16 PM

BackcountrySkier13_inAZ

R56 :: Hatch Talk (2007+)

2

09-05-2014 03:04 PM