DIY For Timing Chain Replaement

#51

__________________

Your Trusted Source For DIY and Parts

FREE SHIPPING over $99 click here

MINI Parts | DIY Help | Facebook | Twitter | Instagram | YouTube | Promos

888.280.7799 | 6am - 5pm PST

FREE SHIPPING over $99 click here

MINI Parts | DIY Help | Facebook | Twitter | Instagram | YouTube | Promos

888.280.7799 | 6am - 5pm PST

#53

Replacing Timing Chain -- Yes, and there's a good discussion

So, has anyone actually successfully done this in their own garage? Or even attempted it without success  ? I plan on doing this in the next week or so, the tools are on ebay for about $220. Still cheaper than having someone else do it, by about $900 (I was quoted $1100 for labor only on this from an independant shop, $2000 in labor from the dealer). I am giving myself over a week to do it, so if something comes up I still have some time to find a solution. I thought about trying to make the tools myself, but decided against it, since if they are wrong, I destroy my engine

? I plan on doing this in the next week or so, the tools are on ebay for about $220. Still cheaper than having someone else do it, by about $900 (I was quoted $1100 for labor only on this from an independant shop, $2000 in labor from the dealer). I am giving myself over a week to do it, so if something comes up I still have some time to find a solution. I thought about trying to make the tools myself, but decided against it, since if they are wrong, I destroy my engine

? I plan on doing this in the next week or so, the tools are on ebay for about $220. Still cheaper than having someone else do it, by about $900 (I was quoted $1100 for labor only on this from an independant shop, $2000 in labor from the dealer). I am giving myself over a week to do it, so if something comes up I still have some time to find a solution. I thought about trying to make the tools myself, but decided against it, since if they are wrong, I destroy my engine

? I plan on doing this in the next week or so, the tools are on ebay for about $220. Still cheaper than having someone else do it, by about $900 (I was quoted $1100 for labor only on this from an independant shop, $2000 in labor from the dealer). I am giving myself over a week to do it, so if something comes up I still have some time to find a solution. I thought about trying to make the tools myself, but decided against it, since if they are wrong, I destroy my engine

There is a VERY good three-hour, three-part video on Youtube, going through this step by step. I used that. Some comments of my own:

1. The camshaft locking tool cost me $56 on Ebay. You might want to search some more if all you see is the $220 version. The one I bought has a tiny defect, a piece sticking out toward the turbo so you can't get it on. Hacksaw or grinder solves that.

2. Supposedly you also need a special tool to put in the new crankshaft seal. I saw on a thread here that you can use a female coupling for 2" PCV pipe ($1.59 at my local hardware), a small block of wood and a hammer (hammer very gently). Note: the coupling, not pcv pipe.

3. There is a special tool to hold the crankshaft pulley in place while you torque the main crankshaft bolt. It's about $75. Instead, I used the shaft of a bar clamp, which fits through a slot in the pulley into the two slots above and below 9:00 when you're facing the pulley. Upper slot is for removal, lower for putting it back on. It's actually easier this way than with the special tool. With the special tool, you need either super strength or someone else to hold the special tool while you torque.

4. The torque spec for that bold used to be 36.8 foot-pounds plus 100 degrees. Now, it's 36.8 plus 180 degrees, a lot more. Using a breaker bar with a piece of pipe on the end, I did that torque with one hand while holding the bottom of the bar clamp through the slot in the pulley into the indent in the engine. It took moderate effort; I'm 70 yrs old and 160 pounds.

5. Whichever way you go, dealer or indy or DIY, get it done. Very important. If the chain flops too lose, you lose all timing and shards of your guides go all over the oil sump.

6. Another special tool you might need is the pair of tools to turn the spring on the tensioner for the auxiliary belt. Mine has a hex bolt, but none of my wrenches fit it. For some reason, the 12-point special wrench did. They send you two sizes. Presumably, mini used two different bolt heads.

7. Some of the timing chain kits you can buy don't have the three special bolts that hold the guides in place. Readings tell me that you must replace these bolts. Pelicanparts.com has everything you need.

8. Some people in this thread discuss trouble getting the new tensioner in. The only trouble I had was that I didn't remove the hoses behind it (too much work) so I had to push against the hose with the round end of a wrench to make room. Hand-tightened as far as I could, then used the torque wrench and the 27mm socket. Didn't strike me as being difficult. Just be nice to the hoses that are in the way.

The real trick to this job is to study the DIY here and the three-hour, three-part video on youtube, gather everything you need beforehand, and take your time. The last steps -- checking that your timing is still right -- are very important.

P.S. One more trick: You absolutely MUST clean out the oil pan if there is any breakage at all in your timing chain guides. In the video I cited, the guy uses a spreader tool he had to remove the really strong exhaust clamp you have to take off. I couldn't find his tool anywhere, but two big fat Phillips screwdrivers, inserted into the bolt holes of this clamp, can be used to expand it and remove/replace it.

P.P.S. There is also some comment about the handle of the crankshaft locking tool in the cheapo kits breaking off Mine did, but the tool functions fine without it if you use locking pliers and maybe a big screwdriver for leverage to get it off. Also, go to the crankshaft pulley and feel the play; take all tension off the locking tool to get it out easier.

Last edited by OldHoopsJunkie; 04-19-2017 at 03:16 PM.

#54

#55

Started the timing chain replacement last weekend.

Got to the step where I pull out the tensioner for the first time in the procedure - the tensioner was only hand tightened it seemed....basically backing out. Yikes! Saved it just in time. For 160,000 miles the engine it is very clean. No sludge and no discoloration from heat. Also, I am following the Bentley manual to reassemble but wasn't working for me. I read other places to reassemble everything, then pretension, and then tighten the cam and crank bolts. I will try this method this weekend. So basically when you pretension you turn the cam sprockets in the process which removes the slack.

Got to the step where I pull out the tensioner for the first time in the procedure - the tensioner was only hand tightened it seemed....basically backing out. Yikes! Saved it just in time. For 160,000 miles the engine it is very clean. No sludge and no discoloration from heat. Also, I am following the Bentley manual to reassemble but wasn't working for me. I read other places to reassemble everything, then pretension, and then tighten the cam and crank bolts. I will try this method this weekend. So basically when you pretension you turn the cam sprockets in the process which removes the slack.

#56

Started the timing chain replacement last weekend.

Got to the step where I pull out the tensioner for the first time in the procedure - the tensioner was only hand tightened it seemed....basically backing out. Yikes! Saved it just in time. For 160,000 miles the engine it is very clean. No sludge and no discoloration from heat. Also, I am following the Bentley manual to reassemble but wasn't working for me. I read other places to reassemble everything, then pretension, and then tighten the cam and crank bolts. I will try this method this weekend. So basically when you pretension you turn the cam sprockets in the process which removes the slack.

Got to the step where I pull out the tensioner for the first time in the procedure - the tensioner was only hand tightened it seemed....basically backing out. Yikes! Saved it just in time. For 160,000 miles the engine it is very clean. No sludge and no discoloration from heat. Also, I am following the Bentley manual to reassemble but wasn't working for me. I read other places to reassemble everything, then pretension, and then tighten the cam and crank bolts. I will try this method this weekend. So basically when you pretension you turn the cam sprockets in the process which removes the slack.

Yes. Both camshafts and crankshaft are pinned to time them correctly relative to each other. The cam gears are loose (snug) as well as the crankshaft bolt (snug) to allow the gears to rotate as needed. Once the Tensioner is installed, the tension on the chain between each camshaft gear and crankshaft are now set to operating tension and distance. Without this tension, the relative positions change once you remove the retainers holding the cams and crank.

Once the tension is on, then all of the slack in the chain is taken up at the tensioner. The crankshaft and camshaft gears rotate to equilibrium and the bolts can then be tightened to the correct torques.

NOTE: The tensioner guide must also be in position. If it is not installed, the chain distance between the cam gears changes (also changing the relative timing between the two cams). In other words, the extra few millimeters of chain length to go over the curved surface between the two gears causes the intake cam to rotate slightly clockwise relative to the exhaust gear. The extra chain distance is coming from the tensioner side (causing the tensioner to be pushed back in just slightly also).

Good luck!!! Make sure you hand rotate twice and reinstall cam locks and crank pin to verify.

#57

Thanks for the feedback. This really isn't a difficult job. Slight learning curve. Hopefully no issues after start up. I'm using a 1/4" beam style torque wrench to torque the tensioner because

it's the only wrench I can find that goes that low.

Also, the exhaust cam bolt was on so tight the splines on the head of the bolt started to break off on first removal. Almost didn't get it off.

Also, accidentally torqued the exhaust bolt to spec and then 180 - oops should have been to spec and then 90 or 100 degrees. Pay attention and read the manually slowly. Don't rush.

Side note: I read something about torquing the bolts at a 45 degree angle. This makes no sense to me. Does this ring a bell for anyone?

I don't am on attempting this just curious what this was about. Read it in one of the threads.

it's the only wrench I can find that goes that low.

Also, the exhaust cam bolt was on so tight the splines on the head of the bolt started to break off on first removal. Almost didn't get it off.

Also, accidentally torqued the exhaust bolt to spec and then 180 - oops should have been to spec and then 90 or 100 degrees. Pay attention and read the manually slowly. Don't rush.

Side note: I read something about torquing the bolts at a 45 degree angle. This makes no sense to me. Does this ring a bell for anyone?

I don't am on attempting this just curious what this was about. Read it in one of the threads.

#59

#60

The bolts are the same, the cam gears are similar material, and the intake and exhaust cams are the same diameter at the bolt end. This begs the question why one would be at 90 degrees, but the other at 180 degrees.

I cannot confirm with absolute certainty, but when I asked the question, there was a confident reply that I searched and found that a person with authority stated that the spec was changed from 90 to 180 at some point for all three bolts.

You may want to research more. I torqued all three to 180 degrees past the torque spec.

I cannot confirm with absolute certainty, but when I asked the question, there was a confident reply that I searched and found that a person with authority stated that the spec was changed from 90 to 180 at some point for all three bolts.

You may want to research more. I torqued all three to 180 degrees past the torque spec.

#61

Latest version off Bentley says intake - plus 180 and exhaust - plus 90 degrees.

Mid 2014 edition.

I finished the job but noticed something.

I have a 2009 MCS - build date 10/2008.

The crank bolt had a washer on it.

But the new crank bolt does not have a washer.

So, washer or not on the crank bolt?

The ECS kit did not come with a washer for the crank. The parts diagrams from oem.com doesn't show a separate washer but it kinda looks like one is in the diagram. But the washer isn't sold separately.

Mid 2014 edition.

I finished the job but noticed something.

I have a 2009 MCS - build date 10/2008.

The crank bolt had a washer on it.

But the new crank bolt does not have a washer.

So, washer or not on the crank bolt?

The ECS kit did not come with a washer for the crank. The parts diagrams from oem.com doesn't show a separate washer but it kinda looks like one is in the diagram. But the washer isn't sold separately.

Last edited by timski; 05-26-2017 at 09:59 PM.

#64

I bought my kit from ECS and the crankshaft bolt does NOT have a loose washer, but an incorporated one in the bolt head (genuine Mini part). The thread length is the same as the original bolt with the washer. I installed without the old washer.

i see your engine is an N14, so it has one VANOS gear and one regular gear for the cams. Mine is a N12 with two VANOS gears. This is why I believe both are torqued to +180 degrees. You might be right with the plain gear only being torqued to +90 degrees.

i see your engine is an N14, so it has one VANOS gear and one regular gear for the cams. Mine is a N12 with two VANOS gears. This is why I believe both are torqued to +180 degrees. You might be right with the plain gear only being torqued to +90 degrees.

#65

Very good thread. Thanks for the help.

Said and done - pretty easy job.

Complicating the job were damaged top chain guide bracket threads. Previous owner used a heli-coil which came out upon bolt removal.

So I had to re-drill slightly and insert a new heli-coil. 15 ft lb seems like a lot for a 6mm bolt.

Engine going back in soon.

Said and done - pretty easy job.

Complicating the job were damaged top chain guide bracket threads. Previous owner used a heli-coil which came out upon bolt removal.

So I had to re-drill slightly and insert a new heli-coil. 15 ft lb seems like a lot for a 6mm bolt.

Engine going back in soon.

#66

Yes, it just has the bolt. The full kits have the bolts and hardware.

__________________

MINI Guru/ MINI Owner Since 2004 | NEW Lifetime Part Replacement | Local Pickup

Milltek | Genuine MINI | Forge Motorsport | NM Engineering | ECS Performance | M7 Speed

Customer Service Hours: 8am-8pm EST|Sales Team Hours: 8am-11pm | SAT 10am-7pm 800.924.5172

MINI Guru/ MINI Owner Since 2004 | NEW Lifetime Part Replacement | Local Pickup

Milltek | Genuine MINI | Forge Motorsport | NM Engineering | ECS Performance | M7 Speed

Customer Service Hours: 8am-8pm EST|Sales Team Hours: 8am-11pm | SAT 10am-7pm 800.924.5172

#67

R56 N14 and N18 engine timing chain replacement differences

This is a short description of what is different when changing the timing chain and all other related timing chain components on a N18B16A engine, which is used in the 2012 R56 Mini Cooper S (car code R56 LCI Type Code SV31). Compared to the earlier 2007+ N14B16A (Car code R56 MF71). The N18B16A engine is the slightly improved or updated engine found in the 2011 R56 midlife Mini Cooper S upgrade (aka R56 LCI). There are a lot of videos and instructions on how to change the timing chain on the older N14B16A engine but few on the newer N18B16A engine. Therefore, I am creating this write up. Also, some parts may be different so check which engine you have. In summary the newer N18 engine was used from 2011 onwards, and the N14 engine was used from 2008 onwards, but these dates may not be the same in all countries. Overall the process is very similar for both engine except that,

Mini Adventure, strongly recommended, there are 3 videos (this is the old N14 engine but 90% of what is here is still good):

Eric the Car Guy (also very good, also old N14 engine, but again most is good):

Two Guys (also old N14 engine)

Maic Salazar (new N18 engine)

BMP, some good N18 timing tricks here, but they did not use new camshaft bolts:

Recommended for Torque specs and official processes:https://www.newtis.info/tisv2/a/en/r56-cooper-s-hat/

Part numbers for 2012 LCI R56 Cooper S Mini:https://www.realoem.com/bmw/enUS/par...-Mini-Cooper_S

First pic of the different camshaft locking tool for the N18 engine, also the locations for adjusting the camshafts with a spanner.

Pictures of INLET and EXHAUST VANOS

Chain tensioner location, it is much easier to remove and install if you take the pipe off.

How to initially seat the crankshaft seal (not the official way).

How to gently get the crankshaft seal in, do this slowly and with small gentle taps.

Measure all around the crankshaft seal to see that it is seated equidistantly all around the rim.

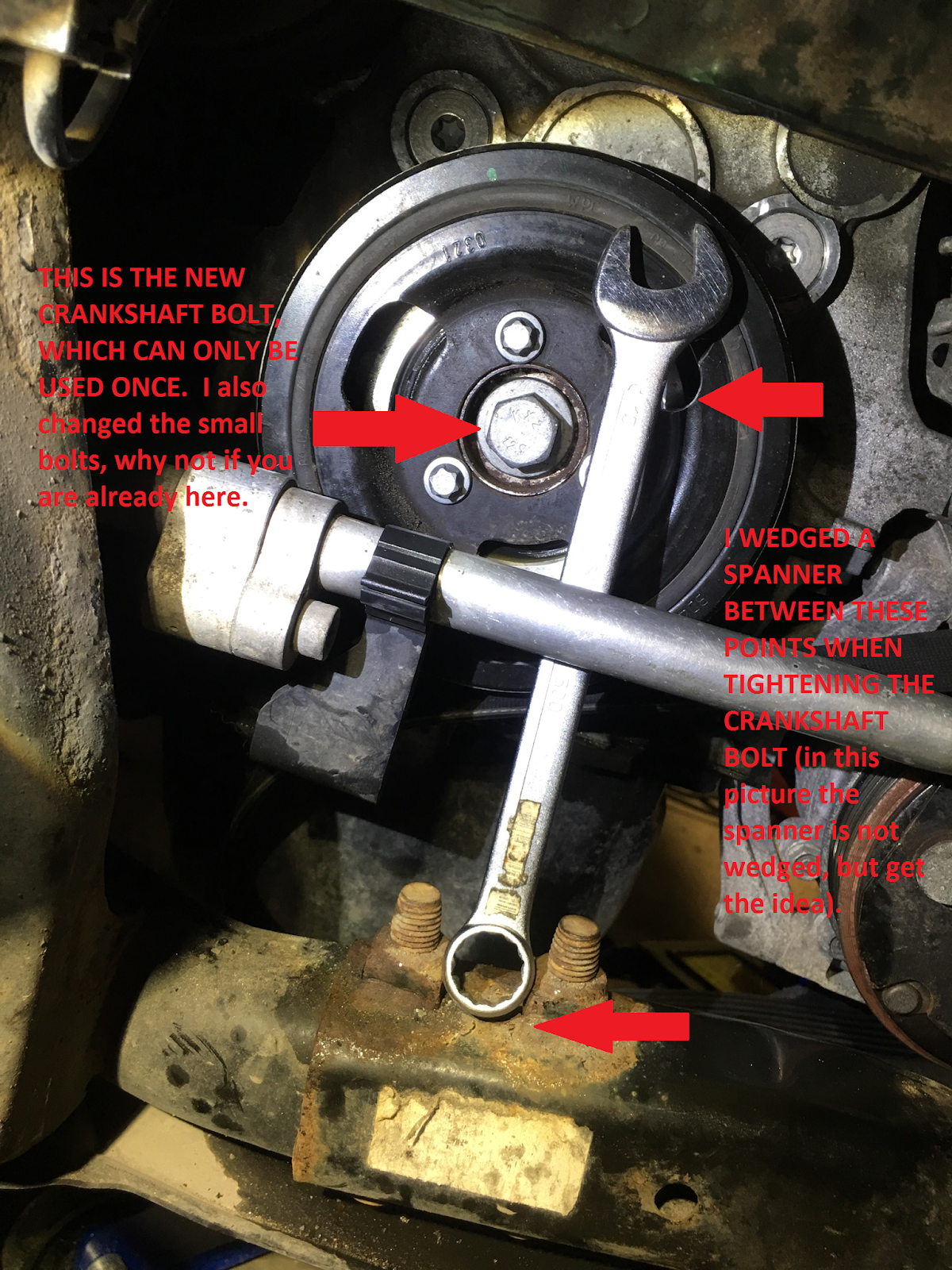

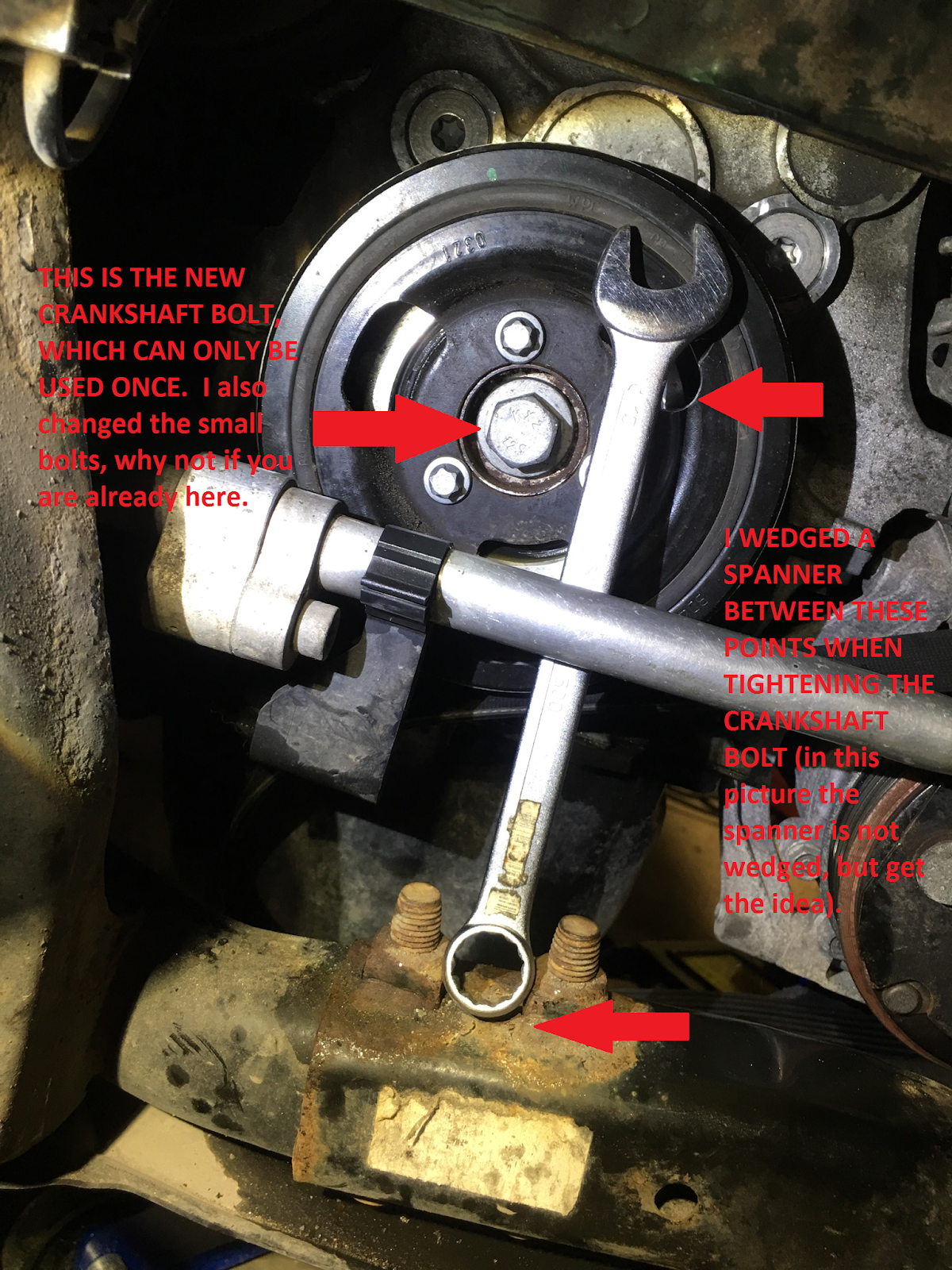

How to hold the crankshaft in place when tightening the crankshaft bold, if you do not have all the official tools. Be careful if you still have the flywheel locking tool still in, the flywheel locking tool will not be sufficiently strong to hold, and you may break it, which is not good.

Picture of new and old chain, old chain may have been very slightly stretched. But I think that I had a sticking chain tensioner. But you do not know unless you take the camshaft cover off or remove the timing chain guides.

Good luck, as I say the new N18 engine is very similar to the N14 engine, but there are a couple small changes. Make sure you get the correct parts for the correct engine.

typo

- The N18 engine needs a different camshaft locking\holder alignment tool than the N14 engine.

- This means also that the spanner size used to adjust the camshaft is a different size (see pics)

- The N18 engine has 2 VANOS sprockets, compared to one VANOS for the earlier N14 engine (see pics)

- This means also that the spanner size used to adjust the camshaft is a different size (see pics)

- The plastic cam cover or rocker cover is different, but the bolts are in the same places (use extra gasket sealant), and do not overtighten the cam cover bolts.

- The VANOS and Crankshaft bolts are “SINGLE USE” (do not reuse the olds ones). They have very specific tightening torques plus extra turning degrees after torquing them.

- One VANOS is for the intake valves/camshaft (labelled “IN”) and the other is for the exhaust valves/camshaft (labelled “EX”). See pics below.

- since taking of the cross member involves removing the headlights these will need to be checked and adjusted when reinstalled, so that you do not blind other motorists when driving in the dark.

- The rubber crankshaft seal also needs to be replaced, but I used the end of a small siphon to get it seated to start with, then I used the end of a socket extension to very carefully seat it in further. Obviously I put engine oil on the seal to aid the seating of the seal. Then going around the seal and very gently tapping it in. Then measuring to make sure that it was in equidistant all around. See pics.

- Also, the crankshaft bolt is a single use item with specific torque and then extra turn tightening requirements, I used a spanner wedged into the pulley or “harmonic balancer” to stop it from turning while tightening.

- You do not need all the specific tools for the crankshaft seal and bolt removal, “necessity is the mother of all invention”, so take your time and solve mechanical problems safely. All engineers and mechanics have to. Also, when tightening the crankshaft bolt I still had the flywheel stopper in, but do not use this to take all the strain, I used the spanner wedged into the crankshaft pulley, see pic.

- I did not get a rattle but I got some engine faults codes (2DA2, 2C58 and 2DA0), the old chain was maybe 1-2mm longer than the new one (which should not be an issue). But the old timing chain tensioner was sticking, (discovered when removed). Also, none of my plastic timing chain guides were broken when I took out the old timing chain and guides. So the problem may have been a sticking, old tensioner. But since I had all the bits, and there was a problem, this was a good overall service. The car was 7 yrs old, and had 40,000km on the clock.

At every stage which involved a lot of time taking out bits to get to the timing chain and engine, I put the bolts and pieces in numbered plastic bags so that I could remember to reinstall in reverse order.

Mini Adventure, strongly recommended, there are 3 videos (this is the old N14 engine but 90% of what is here is still good):

Eric the Car Guy (also very good, also old N14 engine, but again most is good):

Two Guys (also old N14 engine)

Maic Salazar (new N18 engine)

Recommended for Torque specs and official processes:https://www.newtis.info/tisv2/a/en/r56-cooper-s-hat/

Part numbers for 2012 LCI R56 Cooper S Mini:https://www.realoem.com/bmw/enUS/par...-Mini-Cooper_S

First pic of the different camshaft locking tool for the N18 engine, also the locations for adjusting the camshafts with a spanner.

Pictures of INLET and EXHAUST VANOS

Chain tensioner location, it is much easier to remove and install if you take the pipe off.

How to initially seat the crankshaft seal (not the official way).

How to gently get the crankshaft seal in, do this slowly and with small gentle taps.

Measure all around the crankshaft seal to see that it is seated equidistantly all around the rim.

How to hold the crankshaft in place when tightening the crankshaft bold, if you do not have all the official tools. Be careful if you still have the flywheel locking tool still in, the flywheel locking tool will not be sufficiently strong to hold, and you may break it, which is not good.

Picture of new and old chain, old chain may have been very slightly stretched. But I think that I had a sticking chain tensioner. But you do not know unless you take the camshaft cover off or remove the timing chain guides.

Good luck, as I say the new N18 engine is very similar to the N14 engine, but there are a couple small changes. Make sure you get the correct parts for the correct engine.

typo

Last edited by valle; 11-26-2019 at 08:00 AM. Reason: Typo in model number

#69

Brilliant writeup

This is a short description of what is different when changing the timing chain and all other related timing chain components on a N18B16A engine, which is used in the 2012 R56 Mini Cooper S (car code R56 LCI Type Code SV31). Compared to the earlier 2008+ N14B16A (Car code R56 M71). The N18B16A engine is the slightly improved or updated engine found in the 2011 R56 midlife Mini Cooper S upgrade (aka R56 LCI). There are a lot of videos and instructions on how to change the timing chain on the older N14B16A engine but few on the newer N18B16A engine. Therefore, I am creating this write up. Also, some parts may be different so check which engine you have. In summary the newer N18 engine was used from 2011 onwards, and the N14 engine was used from 2008 onwards, but these dates may not be the same in all countries. Overall the process is very similar for both engine except that,

Mini Adventure, strongly recommended, there are 3 videos (this is the old N14 engine but 90% of what is here is still good): https://www.youtube.com/watch?v=HQyyGEg7uSQ&t=388s

Eric the Car Guy (also very good, also old N14 engine, but again most is good): https://www.youtube.com/watch?v=VoPz9sEvYN4

Two Guys (also old N14 engine) https://www.youtube.com/watch?v=zWgcPTjcvjg&t=19s

Maic Salazar (new N18 engine) https://youtube.com/watch?v=QRI7IONI0SA&t=2692s

BMP, some good N18 timing tricks here, but they did not use new camshaft bolts: https://www.youtube.com/watch?v=8xKN9fcFtzc

Recommended for Torque specs and official processes: https://www.newtis.info/tisv2/a/en/r56-cooper-s-hat/

Part numbers for 2012 LCI R56 Cooper S Mini: https://www.realoem.com/bmw/enUS/par...-Mini-Cooper_S

First pic of the different camshaft locking tool for the N18 engine, also the locations for adjusting the camshafts with a spanner.

Pictures of INLET and EXHAUST VANOS

Chain tensioner location, it is much easier to remove and install if you take the pipe off.

How to initially seat the crankshaft seal (not the official way).

How to gently get the crankshaft seal in, do this slowly and with small gentle taps.

Measure all around the crankshaft seal to see that it is seated equidistantly all around the rim.

How to hold the crankshaft in place when tightening the crankshaft bold, if you do not have all the official tools. Be careful if you still have the flywheel locking tool still in, the flywheel locking tool will not be sufficiently strong to hold, and you may break it, which is not good.

Picture of new and old chain, old chain may have been very slightly stretched. But I think that I had a sticking chain tensioner. But you do not know unless you take the camshaft cover off or remove the timing chain guides.

Good luck, as I say the new N18 engine is very similar to the N14 engine, but there are a couple small changes. Make sure you get the correct parts for the correct engine.

- The N18 engine needs a different camshaft locking\holder alignment tool than the N14 engine.

- This means also that the spanner size used to adjust the camshaft is a different size (see pics)

- The N18 engine has 2 VANOS sprockets, compared to one VANOS for the earlier N14 engine (see pics)

- This means also that the spanner size used to adjust the camshaft is a different size (see pics)

- The plastic cam cover or rocker cover is different, but the bolts are in the same places (use extra gasket sealant), and do not overtighten the cam cover bolts.

- The VANOS and Crankshaft bolts are “SINGLE USE” (do not reuse the olds ones). They have very specific tightening torques plus extra turning degrees after torquing them.

- One VANOS is for the intake valves/camshaft (labelled “IN”) and the other is for the exhaust valves/camshaft (labelled “EX”). See pics below.

- since taking of the cross member involves removing the headlights these will need to be checked and adjusted when reinstalled, so that you do not blind other motorists when driving in the dark.

- The rubber crankshaft seal also needs to be replaced, but I used the end of a small siphon to get it seated to start with, then I used the end of a socket extension to very carefully seat it in further. Obviously I put engine oil on the seal to aid the seating of the seal. Then going around the seal and very gently tapping it in. Then measuring to make sure that it was in equidistant all around. See pics.

- Also, the crankshaft bolt is a single use item with specific torque and then extra turn tightening requirements, I used a spanner wedged into the pulley or “harmonic balancer” to stop it from turning while tightening.

- You do not need all the specific tools for the crankshaft seal and bolt removal, “necessity is the mother of all invention”, so take your time and solve mechanical problems safely. All engineers and mechanics have to. Also, when tightening the crankshaft bolt I still had the flywheel stopper in, but do not use this to take all the strain, I used the spanner wedged into the crankshaft pulley, see pic.

- I did not get a rattle but I got some engine faults codes (2DA2, 2C58 and 2DA0), the old chain was maybe 1-2mm longer than the new one (which should not be an issue). But the old timing chain tensioner was sticking, (discovered when removed). Also, none of my plastic timing chain guides were broken when I took out the old timing chain and guides. So the problem may have been a sticking, old tensioner. But since I had all the bits, and there was a problem, this was a good overall service. The car was 7 yrs old, and had 40,000km on the clock.

At every stage which involved a lot of time taking out bits to get to the timing chain and engine, I put the bolts and pieces in numbered plastic bags so that I could remember to reinstall in reverse order.

Mini Adventure, strongly recommended, there are 3 videos (this is the old N14 engine but 90% of what is here is still good): https://www.youtube.com/watch?v=HQyyGEg7uSQ&t=388s

Eric the Car Guy (also very good, also old N14 engine, but again most is good): https://www.youtube.com/watch?v=VoPz9sEvYN4

Two Guys (also old N14 engine) https://www.youtube.com/watch?v=zWgcPTjcvjg&t=19s

Maic Salazar (new N18 engine) https://youtube.com/watch?v=QRI7IONI0SA&t=2692s

BMP, some good N18 timing tricks here, but they did not use new camshaft bolts: https://www.youtube.com/watch?v=8xKN9fcFtzc

Recommended for Torque specs and official processes: https://www.newtis.info/tisv2/a/en/r56-cooper-s-hat/

Part numbers for 2012 LCI R56 Cooper S Mini: https://www.realoem.com/bmw/enUS/par...-Mini-Cooper_S

First pic of the different camshaft locking tool for the N18 engine, also the locations for adjusting the camshafts with a spanner.

Pictures of INLET and EXHAUST VANOS

Chain tensioner location, it is much easier to remove and install if you take the pipe off.

How to initially seat the crankshaft seal (not the official way).

How to gently get the crankshaft seal in, do this slowly and with small gentle taps.

Measure all around the crankshaft seal to see that it is seated equidistantly all around the rim.

How to hold the crankshaft in place when tightening the crankshaft bold, if you do not have all the official tools. Be careful if you still have the flywheel locking tool still in, the flywheel locking tool will not be sufficiently strong to hold, and you may break it, which is not good.

Picture of new and old chain, old chain may have been very slightly stretched. But I think that I had a sticking chain tensioner. But you do not know unless you take the camshaft cover off or remove the timing chain guides.

Good luck, as I say the new N18 engine is very similar to the N14 engine, but there are a couple small changes. Make sure you get the correct parts for the correct engine.

The following users liked this post:

valle (11-26-2019)

#70

Great info! Im gonna link your info on the crankshaft seal to my DIY instructions: https://www.northamericanmotoring.co...ml#post4118907

The following users liked this post:

valle (11-26-2019)

#72

Thanks, I read your very good write up too and I was also going to use a pipe to seat and install the crankshaft seal. But the siphon was next to me and it fitted, fortuitous accident of fortune. Please note the siphon is not strong enough to push the crankshaft seal in all the way and I cut off the small hanger hole (which you see on the picture) to make the siphon fit properly. Concerning the usage of the spanner to hold the crankshaft via the crankshaft pulley be careful with this, in the picture it is not wedged in properly as I forgot to take the picture when I was doing it. The torque on this is very high and it requires an extra turn after the torquing has been done. Please see the "TS link" for all torque specs. Also, the spanner (wrench will be discussed later), can slip. So make sure that one end is in between the bolts on the front chassis. You could use a piece of wood or anything else, but be safe. By the way I cleaned off the rust on the bolts, and the member then I painted it with some rust proofing paint. In the picture the rust does not look good. You are correct I am a Brit, but I live in Sweden.

Sometimes you do need the proper tools such as the camshaft and flywheel "TDC" locking tools. But you can be inventive with the crankshaft seal, important thing is take it easy, take your time and do not use to much force on the seal. Gently does it. When torquing the crankshaft bolt if this spanner (wrench) slips you can easily hurt yourself or damage something.

Sometimes you do need the proper tools such as the camshaft and flywheel "TDC" locking tools. But you can be inventive with the crankshaft seal, important thing is take it easy, take your time and do not use to much force on the seal. Gently does it. When torquing the crankshaft bolt if this spanner (wrench) slips you can easily hurt yourself or damage something.

#73

Thanks, great minds think alike. The new crankshaft seal which I used was made by FEBI, it did have a white plastic "seal installer", but it seamed a bit flimsy. Anyway, looks like the method of gently tapping in the seal is quite common. I did this 2 months ago and have put 10,000km on the car since then, and there are no leaks from the crankshaft seal or anywhere else. So this "tapping method", seems to work ok. Glad I could help, and thanks for cross posting. I learn a lot from these forums so nice to give back when I can.

#74

Thanks for all that info. Kudos to showing all the tricks of the trade.

__________________

MINI Guru/ MINI Owner Since 2004 | NEW Lifetime Part Replacement | Local Pickup

Milltek | Genuine MINI | Forge Motorsport | NM Engineering | ECS Performance | M7 Speed

Customer Service Hours: 8am-8pm EST|Sales Team Hours: 8am-11pm | SAT 10am-7pm 800.924.5172

MINI Guru/ MINI Owner Since 2004 | NEW Lifetime Part Replacement | Local Pickup

Milltek | Genuine MINI | Forge Motorsport | NM Engineering | ECS Performance | M7 Speed

Customer Service Hours: 8am-8pm EST|Sales Team Hours: 8am-11pm | SAT 10am-7pm 800.924.5172

#75

Thanks for the feedback, another piece of advice or trick is that if you are not 100% sure that the timing chain has failed (it is not rattling) or the plastic guides are not broken. Then it may be a good idea to only replace the timing chain tensioner (which is as the back of the engine, when standing at the front of the car). In my experience with two R56 Mini Coopers (one 2009 and one 2012). I did not have broken timing chain guides but I strongly suspect that the tensioner was faulty. When I removed the timing chain tensioner and I tested it by depressing (pressing it in) it, it did not move freely but it got stuck as i pressed it in and as it extended back. But by the time I had done this I had already removed the cam cover and all other bits so I replaced all the components required during a timing chain replacement process. There are also longer timing chain tensioners (82mm) as well as the standard tensioners (78 mm). So for the older Mini a couple years ago I just replaced the tensioner with a longer tensioner, this worked. Please note, in neither scenario was I getting the loud timing chain rattle noises.

Now the trick is to find the correct tensioner for your mini, there is the standard one (length wise) and there is the longer one. I have used the longer one on my older mini, and apparently it is used quite often when the timing chain or guides are not broken, rattling but the chain may have been stretched over time.

A quick check (takes an hour or so compared to several hours to replace the whole timing chain components) is to remove the camshaft/engine cover and then you can see with a torch (flashlight) if the the timing chain tensioners have failed. If you do this you need to replace the camshaft cover gasket and put liquid gasket in the corners, but this is explained in the timing chain replacement processes and videos.

Now the trick is to find the correct tensioner for your mini, there is the standard one (length wise) and there is the longer one. I have used the longer one on my older mini, and apparently it is used quite often when the timing chain or guides are not broken, rattling but the chain may have been stretched over time.

A quick check (takes an hour or so compared to several hours to replace the whole timing chain components) is to remove the camshaft/engine cover and then you can see with a torch (flashlight) if the the timing chain tensioners have failed. If you do this you need to replace the camshaft cover gasket and put liquid gasket in the corners, but this is explained in the timing chain replacement processes and videos.