Engine Cooling Fan and other issues

#1

Engine Cooling Fan and other issues

I have just came back from a 6 hr. trip to Seattle for a recall on my 2004 Mini Cooper S. The dealership did a 101 point inspection and found a number of problems. The ones that I feel need immediate attention are these:

First one they recommend replacing engine cooling fan. How difficult is it to replace?

Next recommendation is the crank sensor "O" ring seal. How difficult is it to that job?

Next recommendation is replacing return and feed power steering hoses.

Again is this a difficult job?

First one they recommend replacing engine cooling fan. How difficult is it to replace?

Next recommendation is the crank sensor "O" ring seal. How difficult is it to that job?

Next recommendation is replacing return and feed power steering hoses.

Again is this a difficult job?

#2

Going to move you to the Stock Problems/Issues area.

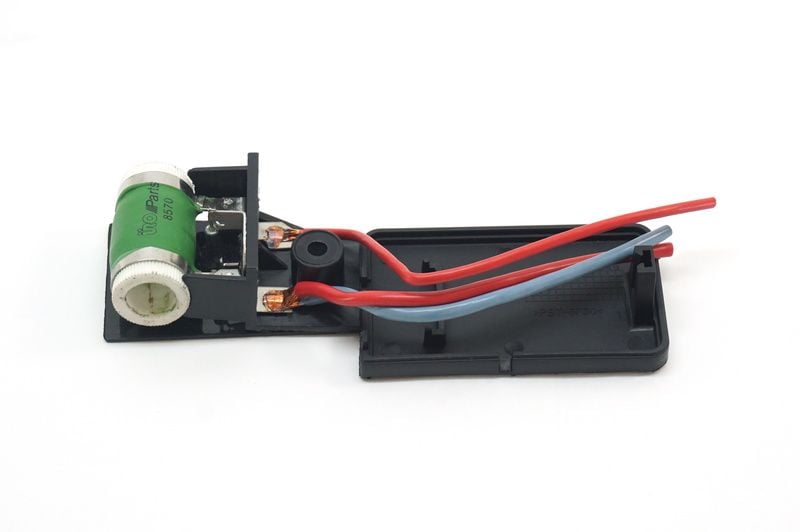

I have some info on your question but sure that others will chime in. 1.) Cooling Fan: do you know whether both high and low speed are shot? You would need to put the car in front service mode so if you pull up a ModMini youtube video so you can see how to do that. If only the low speed is shot then most likely the resistor is shot. You can find a thread in the Sticky section of the Stock Problems/Issues area on how to address. I went this route as only my low speed was shot. The link is below, 2.) Crank Sensor O-ring: Dealer is probably around $300 and this is a $5.00 part but does require you to go front service mode. The biggest issue is knowing how the MINI electric plugs come apart. 3.) Power steering hoses: This appears to be only the supply and return from the reservoir (dealer around $700 for all three, don't know about just the two). This is not too bad of a job but assuming you do not have a lift, be prepared for some fun (car is not high enough to work on easily, and when jacked up the position is too high to be laying flat). I am thinking you need to have a 22 mm socket, perhaps 21, but also an articulating socket adapter. The crush washer is also a PIA to keep in place, I put a small dab of contact cement to hold in place (with only one person it is tough to get the washer to stay on while you are trying to get the hose back together by the driver side tire) and so far after almost a year no adverse effects. If I remember correctly I had to cut the large hose off first in order to get the reservoir off. Try to pump out as much fluid as you can.

https://www.northamericanmotoring.co...-solution.html

I have some info on your question but sure that others will chime in. 1.) Cooling Fan: do you know whether both high and low speed are shot? You would need to put the car in front service mode so if you pull up a ModMini youtube video so you can see how to do that. If only the low speed is shot then most likely the resistor is shot. You can find a thread in the Sticky section of the Stock Problems/Issues area on how to address. I went this route as only my low speed was shot. The link is below, 2.) Crank Sensor O-ring: Dealer is probably around $300 and this is a $5.00 part but does require you to go front service mode. The biggest issue is knowing how the MINI electric plugs come apart. 3.) Power steering hoses: This appears to be only the supply and return from the reservoir (dealer around $700 for all three, don't know about just the two). This is not too bad of a job but assuming you do not have a lift, be prepared for some fun (car is not high enough to work on easily, and when jacked up the position is too high to be laying flat). I am thinking you need to have a 22 mm socket, perhaps 21, but also an articulating socket adapter. The crush washer is also a PIA to keep in place, I put a small dab of contact cement to hold in place (with only one person it is tough to get the washer to stay on while you are trying to get the hose back together by the driver side tire) and so far after almost a year no adverse effects. If I remember correctly I had to cut the large hose off first in order to get the reservoir off. Try to pump out as much fluid as you can.

https://www.northamericanmotoring.co...-solution.html

#3

Going to move you to the Stock Problems/Issues area.

I have some info on your question but sure that others will chime in. 1.) Cooling Fan: do you know whether both high and low speed are shot? You would need to put the car in front service mode so if you pull up a ModMini youtube video so you can see how to do that. If only the low speed is shot then most likely the resistor is shot. You can find a thread in the Sticky section of the Stock Problems/Issues area on how to address. I went this route as only my low speed was shot. The link is below, 2.) Crank Sensor O-ring: Dealer is probably around $300 and this is a $5.00 part but does require you to go front service mode. The biggest issue is knowing how the MINI electric plugs come apart. 3.) Power steering hoses: This appears to be only the supply and return from the reservoir (dealer around $700 for all three, don't know about just the two). This is not too bad of a job but assuming you do not have a lift, be prepared for some fun (car is not high enough to work on easily, and when jacked up the position is too high to be laying flat). I am thinking you need to have a 22 mm socket, perhaps 21, but also an articulating socket adapter. The crush washer is also a PIA to keep in place, I put a small dab of contact cement to hold in place (with only one person it is tough to get the washer to stay on while you are trying to get the hose back together by the driver side tire) and so far after almost a year no adverse effects. If I remember correctly I had to cut the large hose off first in order to get the reservoir off. Try to pump out as much fluid as you can.

https://www.northamericanmotoring.co...-solution.html

I have some info on your question but sure that others will chime in. 1.) Cooling Fan: do you know whether both high and low speed are shot? You would need to put the car in front service mode so if you pull up a ModMini youtube video so you can see how to do that. If only the low speed is shot then most likely the resistor is shot. You can find a thread in the Sticky section of the Stock Problems/Issues area on how to address. I went this route as only my low speed was shot. The link is below, 2.) Crank Sensor O-ring: Dealer is probably around $300 and this is a $5.00 part but does require you to go front service mode. The biggest issue is knowing how the MINI electric plugs come apart. 3.) Power steering hoses: This appears to be only the supply and return from the reservoir (dealer around $700 for all three, don't know about just the two). This is not too bad of a job but assuming you do not have a lift, be prepared for some fun (car is not high enough to work on easily, and when jacked up the position is too high to be laying flat). I am thinking you need to have a 22 mm socket, perhaps 21, but also an articulating socket adapter. The crush washer is also a PIA to keep in place, I put a small dab of contact cement to hold in place (with only one person it is tough to get the washer to stay on while you are trying to get the hose back together by the driver side tire) and so far after almost a year no adverse effects. If I remember correctly I had to cut the large hose off first in order to get the reservoir off. Try to pump out as much fluid as you can.

https://www.northamericanmotoring.co...-solution.html

#4

I have just came back from a 6 hr. trip to Seattle for a recall on my 2004 Mini Cooper S. The dealership did a 101 point inspection and found a number of problems. The ones that I feel need immediate attention are these:

First one they recommend replacing engine cooling fan. How difficult is it to replace?

Next recommendation is the crank sensor "O" ring seal. How difficult is it to that job?

Next recommendation is replacing return and feed power steering hoses.

Again is this a difficult job?

First one they recommend replacing engine cooling fan. How difficult is it to replace?

Next recommendation is the crank sensor "O" ring seal. How difficult is it to that job?

Next recommendation is replacing return and feed power steering hoses.

Again is this a difficult job?

As you have to put the modular front end into the service mode to get at the cooling fan changing the crank position sensor o-ring is as easy as writing a "O".

The power steering hoses are a PITA to replace but with will it can be done even for some with little experience.

#6

As the tech did report the cooling fan low speed in-op for the reason to replace the fan, you can count on it just the low speed resistor is shot. Do a search on the forum and you will see it is a very easy fix. If you are not handy with solder iron, I recommend just buy a replacement module (and yes, the fear mongers will tell you it will fail again).

As you have to put the modular front end into the service mode to get at the cooling fan changing the crank position sensor o-ring is as easy as writing a "O".

The power steering hoses are a PITA to replace but with will it can be done even for some with little experience.

As you have to put the modular front end into the service mode to get at the cooling fan changing the crank position sensor o-ring is as easy as writing a "O".

The power steering hoses are a PITA to replace but with will it can be done even for some with little experience.

Replacing the "O" ring, do I take out the two bolts on the bottom of the engine and the one bolt on the engine mount and no others?

How many inches of movement will I expect to move the engine?

How difficult is it to get the motor back into place?

Thanks

#7

On the fan, you most likely heard the high speed fan engage that would mean the temperature was around 234 whereas the low is at 221. Think about it, the car company designs a system to operate around 220 degrees but your car has most likely been operating closer to 230 degrees. Do you think those 10 degrees over time will have an impact on the parts within the engine?

On the o-ring, you are not removing any engine mounts. Watch the Modmini video on Front Service Mode. You are removing the bumper trim, the bumper and the parts (I call them horns) where the bumper is attached to the frame. You do not need to remove the AC condenser, can carefully allow it to rotate down to the ground ( I have a wood tripod made that helps keep it from wiggling around too much).

On the o-ring, you are not removing any engine mounts. Watch the Modmini video on Front Service Mode. You are removing the bumper trim, the bumper and the parts (I call them horns) where the bumper is attached to the frame. You do not need to remove the AC condenser, can carefully allow it to rotate down to the ground ( I have a wood tripod made that helps keep it from wiggling around too much).